North Korea Boiler economizer

Category:

North KoreaBoiler economizer

- Product Description

-

1. what is a boiler economizer

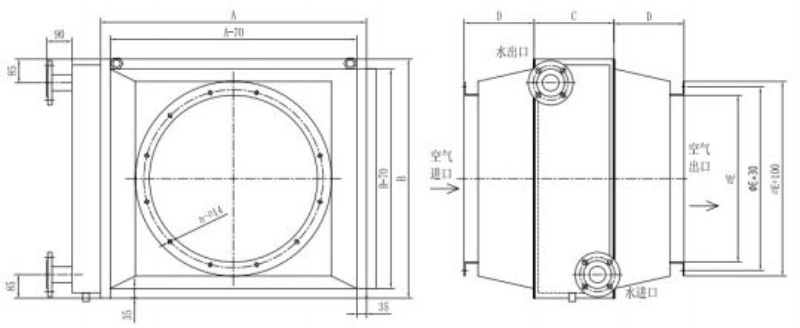

Boiler economizer is another name for waste heat recovery equipment. Because it is used in conjunction with boilers, it is sometimes called boiler economizer, but the working principle and composition of the equipment have not changed. Boiler economizer is an energy-saving device. The structure of the whole equipment is relatively simple. It is mainly composed of carbon steel, alloy steel or stainless steel metal plates. These plates will be arranged in a certain order. In the actual operation process, the medium of heat exchange appears in the form of flue gas-hot water waste heat recovery, flue gas-heat transfer oil, flue gas-air heat exchange and so on. The material used is generally all stainless steel 304 or carbon steel, alloy steel frame with stainless steel or carbon steel, alloy steel spiral finned tube. It has the characteristics of fast heat transfer, energy saving, beautiful appearance and durability.

Working principle of 2. boiler economizer

The principle of boiler economizer is to install a set of equipment at the end of the boiler. When heat exchange is carried out, the flue gas and another heat exchange medium exchange heat in the flue gas. After absorbing a large amount of heat energy, the low-temperature medium returns to the boiler again, which is equivalent to the secondary utilization of waste heat, which improves the performance of steam equipment and reduces energy consumption.

Characteristics of 3. boiler economizer

1. Energy saving efficiency above 10-15%

2, the use of corrosion-resistant steel, life of up to 10 years or more

3. High heat exchange efficiency and efficient recovery of heat in low-temperature flue gas

4, equipment ventilation power is low, can keep the original boiler running state unchanged

5. Widely used for waste heat recovery in various industrial kilns and petroleum and petrochemical industries

6, can be designed according to the specific situation of users

Boiler energy-saving technologies include: boiler flue gas waste heat recovery, boiler body heating surface and fan transformation, boiler operation optimization and adjustment. Among them, the flue gas waste heat recovery and utilization technology is more mature, and the energy saving is considerable. The principle is to use the heat exchanger to recover the heat in the flue gas and improve the efficiency of the boiler. Among them, the more advanced composite phase change heat exchanger can achieve a substantial reduction in the temperature of the flue gas for most boilers, and recover its heat to heat the condensed water, boiler water, domestic water, etc., to achieve energy recovery and efficient use.

Production process

: next page