Flue gas heat exchanger

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

Flue gas heat exchanger

Flue gas heat exchanger is a kind of equipment used to recover heat energy in industrial flue gas to improve energy efficiency and reduce energy costs. Its working principle is basically to transfer the thermal energy in the flue gas to other fluids (usually water or air) to recover and reuse the waste heat. Flue gas heat exchanger is a kind of industrial equipment, which uses high temperature flue gas as heat medium to exchange heat with low temperature medium such as air or aqueous solution.

- Product Description

-

Overview of 1. Flue Gas Heat Exchanger

Flue gas heat exchanger is a kind of equipment used to recover heat energy in industrial flue gas to improve energy efficiency and reduce energy costs. Its working principle is basically to transfer the thermal energy in the flue gas to other fluids (usually water or air) to recover and reuse the waste heat. Flue gas heat exchanger is a kind of industrial equipment, which uses high temperature flue gas as heat medium to exchange heat with low temperature medium such as air or aqueous solution. In addition to playing an important role in heating the medium, the flue gas heat exchanger can also be used for cooling the medium because it can withstand a very wide temperature range.

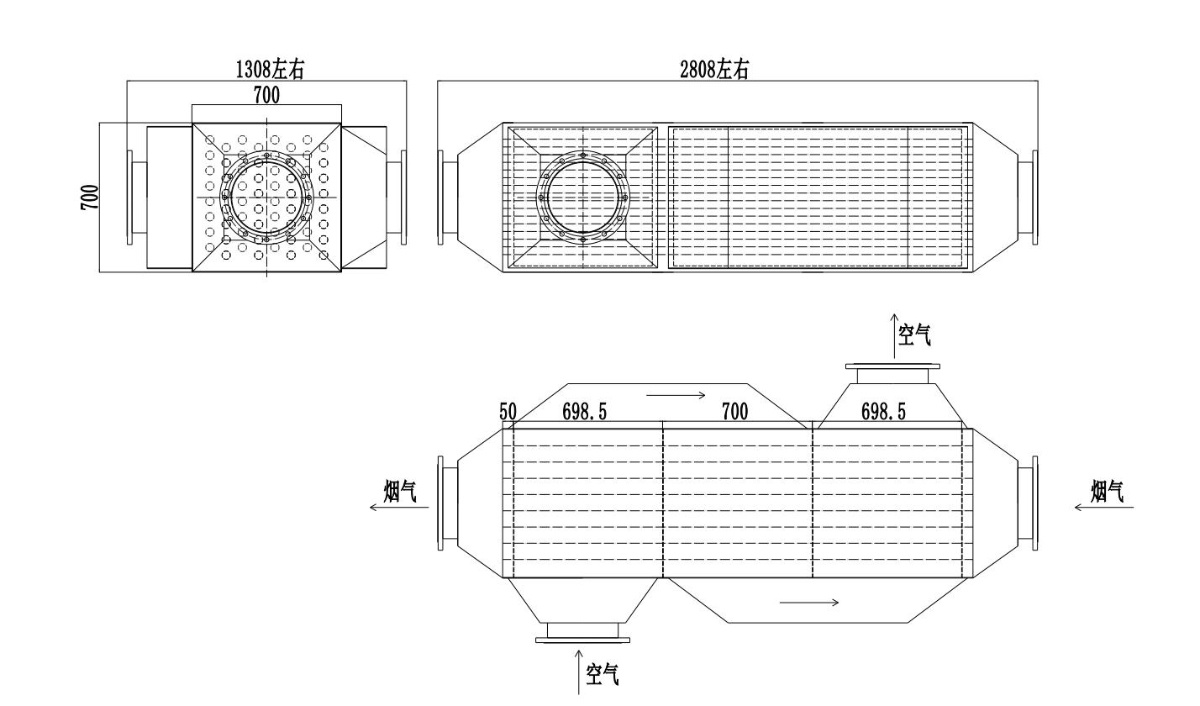

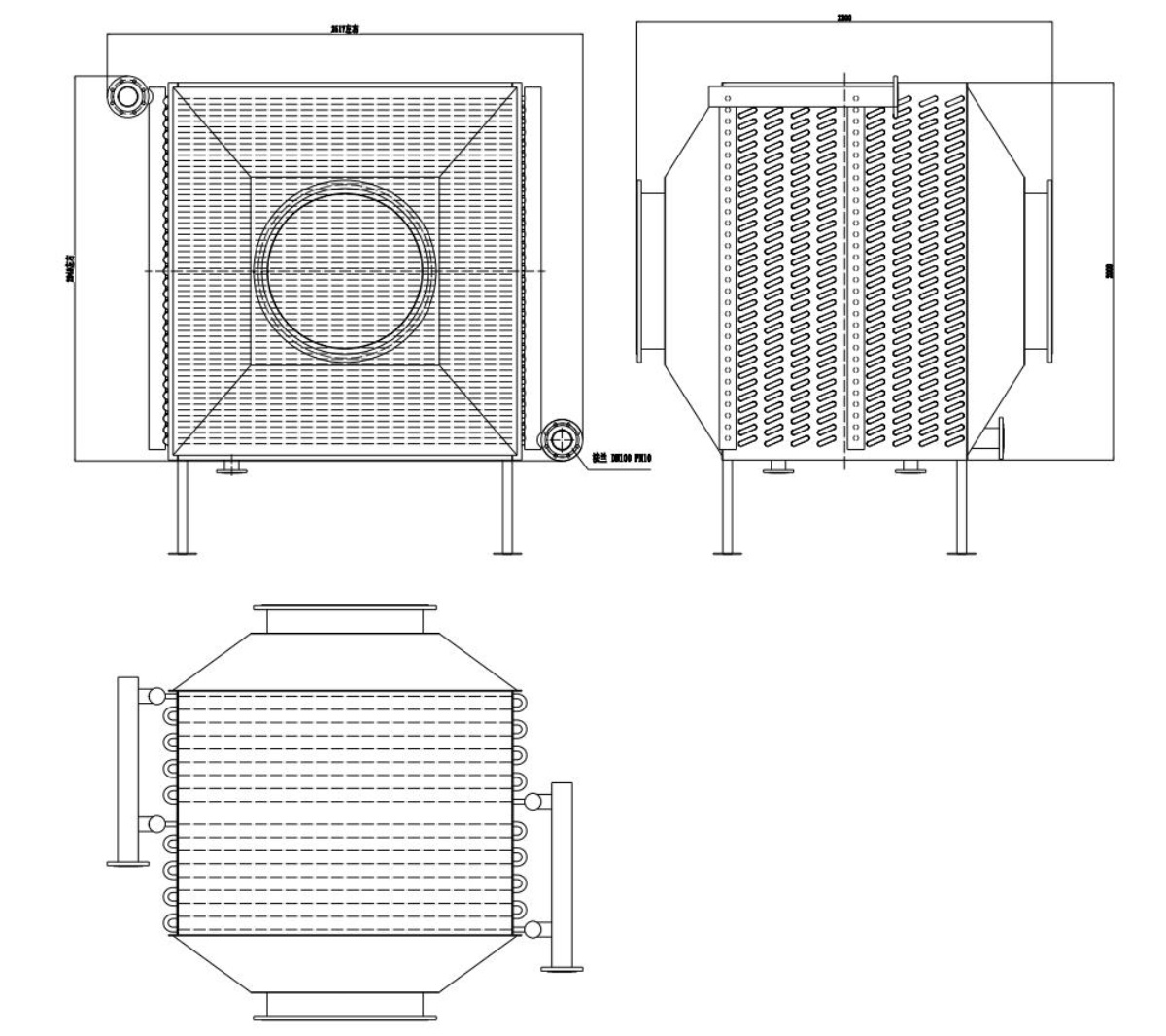

Basic composition of 2. flue gas heat exchanger

1. Heat exchanger core: The core of a heat exchanger is a structure composed of a series of tubes or plates that allow two gas fluids to cross flow in it, thereby achieving heat transfer.

2. Inlet and outlet: The heat exchanger usually has two side ports, one for the hot gas fluid entering the heat exchanger, and the other for the heated gas fluid output.

3. Shell: The shell is the outer shell of the heat exchanger, which is used to surround and protect the core of the heat exchanger. It usually has thermal insulation or insulation to reduce heat loss.

4. Fans or air ducts: Some gas-gas heat exchanger systems may include fans or air ducts to push the gas fluid through the heat exchanger to increase heat exchange efficiency.

Working principle of 3. flue gas heat exchanger

1. Flue gas entry: Flue gas heat exchangers are usually installed in the flue gas discharge pipes of industrial boilers, hot blast stoves, kilns or other combustion equipment. The flue gas generated in the combustion process passes through the flue gas heat exchanger.

2. Heat transfer medium flow: In flue gas heat exchangers, there is usually a heat transfer medium, such as water or air, flowing through the pipes or tube bundles inside the heat exchanger. This heat transfer medium can be heating water used to heat buildings or provide hot water, or boiler water used to generate electricity, depending on the application.

3. Heat exchange: heat transfer between flue gas and heat transfer medium through the heat exchange surface. These surfaces are usually tubes or fins, which transfer the thermal energy of the flue gas to the heat transfer medium, heating the heat transfer medium.

4. Heat transfer medium heating: The heat transfer medium absorbs the heat energy in the flue gas during the heat exchange process, so it heats up. The warmed heat transfer medium can be used for heating, producing hot water, generating electricity, or other industrial processes.

5. Cooled flue gas emission: The flue gas is usually cooled after heat exchange because its heat energy has been transferred to the heat transfer medium. The cooled flue gas is discharged to the atmosphere.

The working principle of the flue gas heat exchanger allows the waste heat generated in the industrial process to be recovered and used to provide hot water, heating, electricity or other purposes. This helps to improve energy efficiency and reduce energy consumption and emissions, thereby reducing environmental impact. Therefore, in industrial and commercial applications, flue gas heat exchanger is an important energy recovery equipment.

Principle of 4. flue gas heat exchanger

The flue gas heat exchanger is an efficient energy recovery device, which can transfer the heat in the high-temperature flue gas to the low-temperature medium, thereby reducing the temperature of the flue gas, and at the same time storing or utilizing the heat. This kind of equipment has a wide range of applications in industrial and civil fields, such as power plants, steel plants, cement plants, etc.

The working principle of the flue gas heat exchanger is based on the principle of thermodynamics, and the energy transfer is realized through the heat exchange between two media with different temperatures. The high temperature flue gas contacts with the low temperature medium in the heat exchanger, and the high temperature flue gas transfers heat to the low temperature medium, so that the flue gas temperature drops, while the low temperature medium absorbs heat and heats up. This heat exchange process can effectively utilize the waste heat in the flue gas and improve the energy efficiency.

Characteristics of 5. flue gas heat exchanger

1. Efficient heat transfer: Gas-gas heat exchangers are designed to maximize heat transfer efficiency. The structure of the heat exchanger core is usually designed to have a large surface area to increase the possibility of heat exchange.

2. Energy saving: By recovering heat from waste heat gas and transferring it to the gas that needs to be heated, the gas-gas heat exchanger helps to save energy. This is especially important in industrial processes.

3. Environmental protection: The use of gas-gas heat exchangers can reduce energy consumption, reduce greenhouse gas emissions, and contribute to environmental protection.

4. Multiple applications: Gas-gas heat exchangers can be applied to a variety of scenarios, including heating, ventilation, air conditioning, waste heat recovery in industrial processes, condensation and vaporization in chemical processes, etc.

5. Suitable for different gases: Gas-gas heat exchangers can usually handle different types of gases, including gas, steam, air, exhaust gas, etc.

6. Maintenance and cleaning: Maintenance is relatively simple, usually only the surface of the heat exchanger core needs to be cleaned regularly to ensure heat transfer efficiency.

In short, the flue gas heat exchanger is a device widely used in industrial and commercial applications for heat transfer and energy recovery. Its high efficiency and environmental characteristics make it an important part of many engineering projects.

Production process

Company Profile

The company's main products include fin tubes, fin tube radiators, fin tube heat exchangers, heaters, air preheaters, air coolers, etc. Product materials include steel, stainless steel, steel-aluminum composite, etc., and are widely used in chemical, petroleum, power, electric power, food, textile, printing and dyeing and other industries. The company strives for survival by quality, seeks benefits from management, takes scientific and technological innovation as the driving force for development, regards integrity as the foundation of the enterprise, and establishes a customer-centered business philosophy. Our products cover nearly 30 provinces, cities, and autonomous regions in China, and we have established long-term cooperative relationships with many of the top 500 companies in the country.

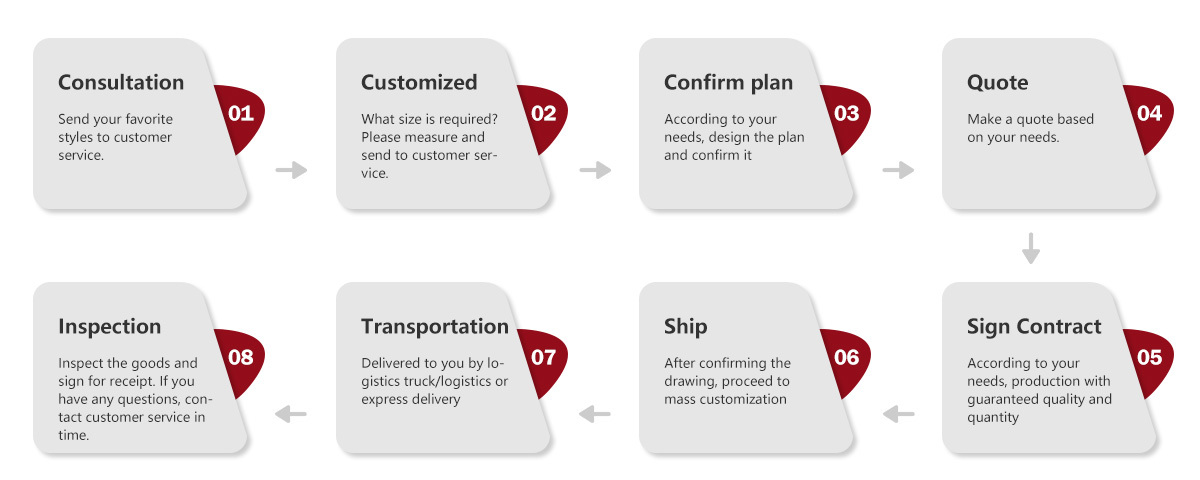

Personalized Customization Process

Product specifications and models, support processing customization

Partner

Qualification

Key words:

Get Quote

Related Products