Papua New Guinea Carbon steel stainless steel finned tube

Category:

Papua New GuineaHigh frequency welding finned tube

- Product Description

-

1. Overview

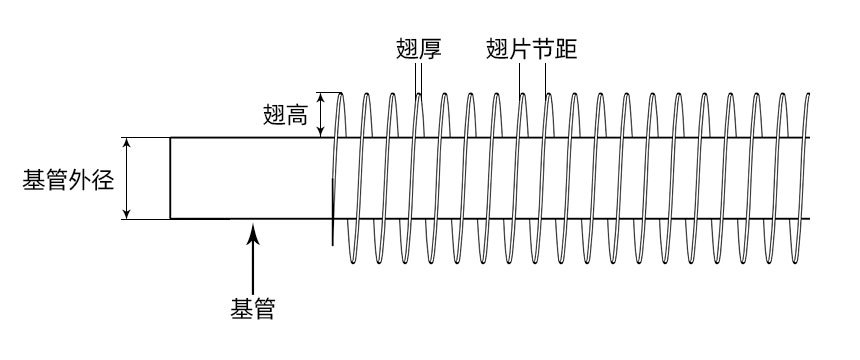

High frequency welding carbon steel stainless steel finned tube is a new, wear-resistant, high-efficiency heat exchange material, is a high-efficiency and energy-saving heat exchange element

2. production process

It uses national-level technology to use high-frequency welding production technology, and uses high-frequency power as the heat source to heat steel strips and stainless steel pipes at the same time, so that they are welded together into one body. It has high heat exchange efficiency, large heat dissipation area, and long service life. Adapt to the characteristics of wide temperature range and high pressure. The production process is to wind the strip steel with a thickness of 0.8-1mm on the finned tube, and at the same time, the high-frequency welding process is adopted to weld the fins on the tube to ensure the joint strength between the tube and the fins, and the metal thermal strength has reached 1.10~1.20 w/kg ℃.

3. features

1. The installation is simple and economical. The maximum length of the high-frequency welding spiral finned tube can reach 6 meters, which reduces the connection point, makes the installation more economical and fast, and reduces the probability of water leakage at the connection.

2. easy maintenance, high frequency welding spiral finned tube after installation, basically no longer need to maintain.

3. High efficiency, high-frequency welding spiral finned tube is full contact welding of fin and steel pipe winding, the heat dissipation area is more than 8 times that of the smooth tube, the interior is smoother, and the internal water flow resistance is small.

4. Long service life, high mechanical strength combined with fins and pipes, tensile strength of more than 200Mpa, all inside and outside the tube using hot galvanizing treatment.

4. Application Areas

It is widely used in waste heat recovery, petrochemical industry, power station boiler, economizer, bus, industrial and civil building heating, refrigeration, medicine drying, wood drying, grain drying system, light industry, electric power, metallurgy, energy and other industries.

Production process