Papua New Guinea Alloy steel carbon steel finned tube

Category:

Papua New GuineaHigh frequency welding finned tube

- Product Description

-

1. Overview

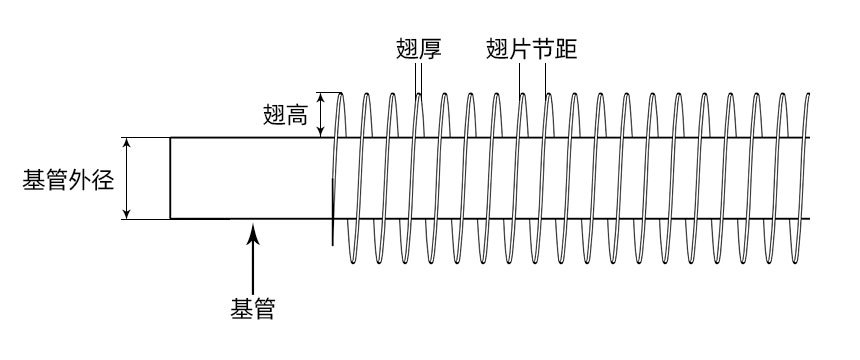

Alloy steel finned tubes are made of alloy steel fins and carbon steel base tubes.

2. production process

When the process of alloy steel finned tube is high frequency welding, the strip steel is spirally welded on the carbon steel base tube on the automatic welding production line. The welding rate of this structure is as high as 98%, the structure is firm and corrosion resistant, and it is suitable for working conditions with harsh environment.

Alloy steel fin tube distance is larger, from 4-8mm, the thickness is generally 0.6-3mm, the unit heat exchange area is small, the contact thermal resistance is relatively large. The high-frequency welding process is used to weld the steel strip and the heat exchange tube together to form an efficient heat transfer surface. In this process, parameters such as welding temperature, time and pressure need to be precisely controlled to ensure welding quality and heat transfer efficiency.

3. features

1. Due to the fast welding speed and the strong self-cooling effect of the weldment, not only the heat affected zone is small, but also the oxidation is not easy to occur, so the organization and performance of the weld are very excellent.

2, corrosion resistance, wear resistance, low contact thermal resistance, high stability, anti ash ability.

3. Large heat exchange area.

4. Application Areas

As an efficient heat exchange element, the application field of finned tube is expanding. In the petroleum, chemical, light industry, electric power, metallurgy, energy and other industries, high-frequency welded finned tubes are widely used in various types of heat exchangers, radiators, economizers, waste heat recovery devices and other equipment. It has won high praise from the majority of users for its efficient and reliable heat transfer performance and durability.

Production process