To provide you with high-quality and efficient heat exchange exclusive solutions |20 years focus on finned tube radiator, heat exchanger design and production strength enterprises

-

Heat ExchangerHeat Exchanger

Heat exchangers are a very good energy-saving device that can reuse energy that would otherwise be wasted. -

Heat SinkHeat Sink

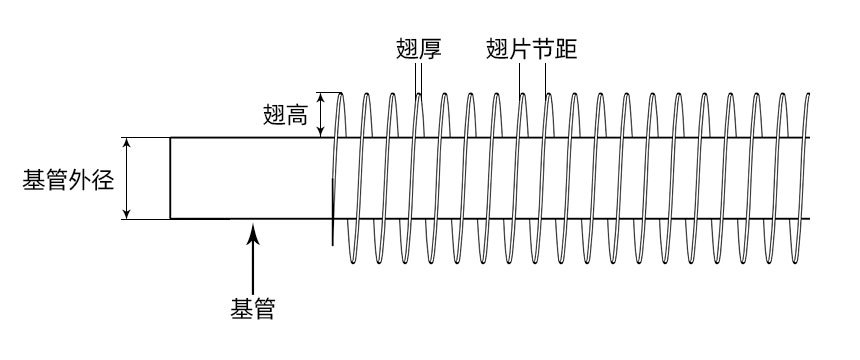

The industrial radiator adopts steel double-circuit (two rows) or multi-circuit (four rows, six rows) structure. The fin tube adopts winding molding process. The base tube is Ф18*2mm, the sheet height is 10mm, and the sheet thickness is 0.3mm. The distance between the sheets is 3mm, with high pressure bearing and corrosion resistance; -

Products

Products

The company's main products include fin tubes, fin tube radiators, fin tube heat exchangers, heaters, air preheaters, air coolers, etc. Product materials include steel, stainless steel, steel-aluminum composite, etc., and are widely used in chemical, petroleum, power, electric power, food, textile, printing and dyeing and other industries. -

About

About

Hebei Rongyang Thermal Energy Equipment Co., Ltd. is a R&D and manufacturer of fin tubes and fin tube equipment. A practitioner who provides technical support in the field of heat transfer and wins reputation with heat exchange efficiency. The company is located in Jizhou, an ancient civilization in Kyushu, in a provincial high-tech development zone. It covers an area of 16,000 square meters and has more than 300 employees. -

News

News

The company strives for survival by quality, seeks benefits from management, takes scientific and technological innovation as the driving force for development, regards integrity as the foundation of the enterprise, and establishes a customer-centered business philosophy. Our products cover nearly 30 provinces, cities, and autonomous regions in China, and we have established long-term cooperative relationships with many of the top 500 companies in the country.

Papua New Guinea Open-toothed finned tube

Category:

Papua New GuineaHigh frequency welding finned tube

- Product Description

-

1. Overview

The open-tooth finned tube is a series of triangular cuts machined on the outer edge of the general annular fin, thereby forming an open-tooth fin shape.

2. production process

The open-tooth fin tube is to open the steel strip before the high-frequency welding of the fins, and then use the skin effect of the high-frequency current to weld the steel strip after the tooth opening to the steel pipe. Is a new, wear-resistant, heat exchange material, is a kind of energy-saving heat exchange components. The weldable diameter is φ25-φ168mm; The thickness of the weldable steel pipe is 1-10mm; The length of the weldable steel pipe is 0.5-15m; The height of the weldable fin is 8-20mm; The thickness of the weldable fin is 0.8-2.5mm; The fin pitch is 4.5-15mm; Weldable materials include carbon steel, low carbon steel and stainless steel.

3. product features

The high-frequency welded open-tooth finned tube has a greater turbulence effect on the gas outside the tube than the non-open-tooth fin, which increases the flow speed of the gas, enables the gas to flow effectively in a turbulent state, and effectively enhances the heat transfer effect. In the case of large gas pressure drop, the open-tooth finned tube improves the heat exchange efficiency and can better prevent dust accumulation.

Four: application areas

Open-tooth finned tubes are often used in boiler economizers and flue gas waste heat recovery equipment.

Contact Information

Do you have any questions about our products or after-sales service?

Simply contact us:

Mobile:+8615503298989

Telephone:0086-318-887-7776

E-mail:hsrongyangnuantong@163.com