Tunisia Non-standard finned tube radiator

Category:

TunisiaNon-standard custom finned tube radiator

- Product Description

-

Overview of 1. finned tube radiator

The finned radiator is the most widely used heat exchanger in gas and liquid heat exchange equipment. It achieves the purpose of heat transfer enhancement by processing fins on ordinary base tubes. The base pipe can be made of steel pipe; stainless steel pipe; copper pipe, etc. Fins can also be used with steel strips; stainless steel strips; copper strips; aluminum strips, etc., which can be customized according to needs.

2. finned tube radiator structure

Fin type radiator can be divided into winding type in fin structure form. Tandem type; Solder plate type; Rolling sheet type, according to the structure form can be divided into SRZ;SRL;GLII;FUL,TL type, etc.

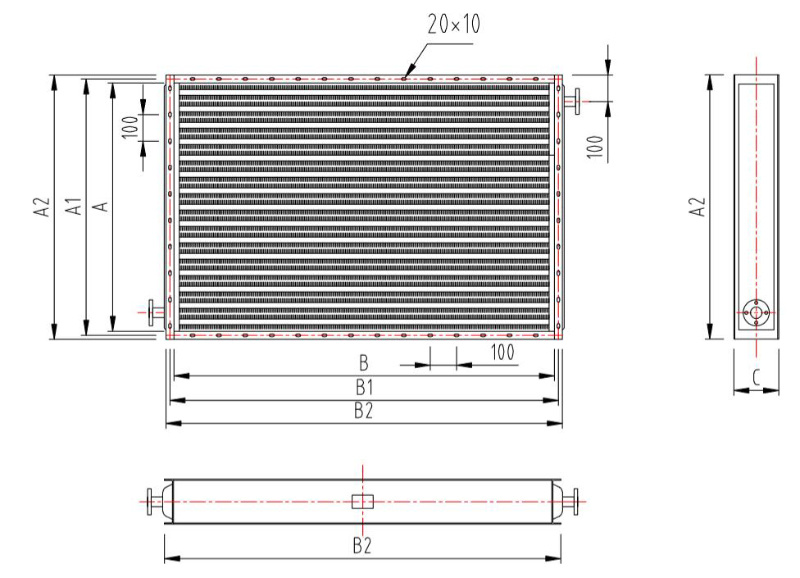

SRZ type finned tube radiator & SRL type radiator & SLZ drying room radiator structure diagram:

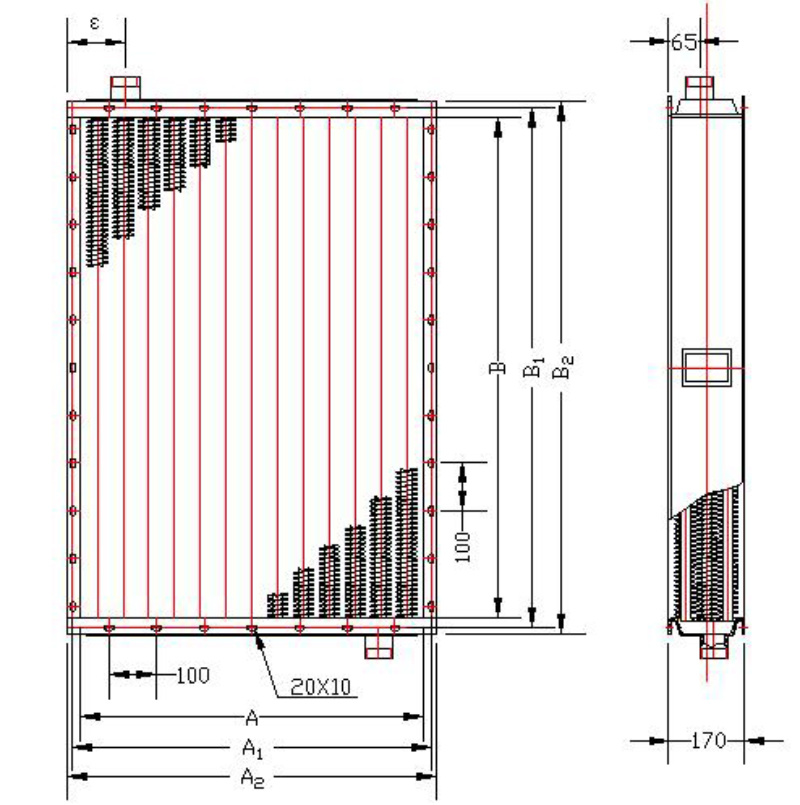

SRQ steam radiator structure diagram:

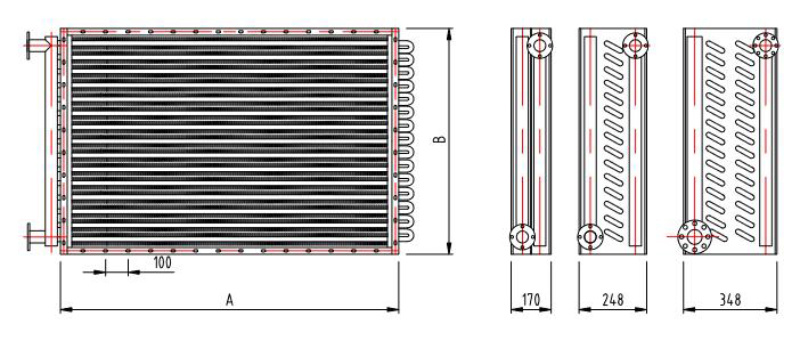

GL type industrial radiator structure diagram:

At present, the most widely used finned radiator is steel-aluminum finned tube (wound sheet steel-aluminum composite finned tube, rolled sheet steel-aluminum composite finned tube), which takes advantage of the pressure resistance of steel pipe and the high thermal conductivity of aluminum. It is compounded on a special machine tool. The thermal contact resistance is almost zero at 210°C. The steel-aluminum composite tube radiator has irreplaceable advantages over other types of finned tube radiators. Finned tube radiators are generally used for heating or cooling air, and have the characteristics of compact structure and large unit heat exchange area.

3. finned tube radiator application field

The finned tube radiator is mainly used for hot air heating, air conditioning, cooling, dehumidification, drying and other projects. It is suitable for heating air with steam or high temperature hot water, and cooling air with salt water or low temperature water. It has been used in dozens of industries. It covers industries such as industrial and mining enterprises, light industry, papermaking, beer malt, starch, chemical industry, national defense, construction, textile printing and dyeing, metallurgy, electric power, electronics, dairy products, food processing, ceramics, hospitals, theaters, etc.

Production process

: next page