Paraguay SRQ Steam Radiator

Category:

ParaguaySRQ Steam Radiator

- Product Description

-

1. SRQ Steam Radiator Overview

1.SRQ steam radiator is composed of steel perforated plate frame and steel heat dissipation finned tube. It is widely used in air heating of drying system and large and medium-sized heating, ventilation and heat exchange system.

2.SRQ steam radiator heat exchange medium: steam (≤ 1.0MPa), hot water (<130 ℃).

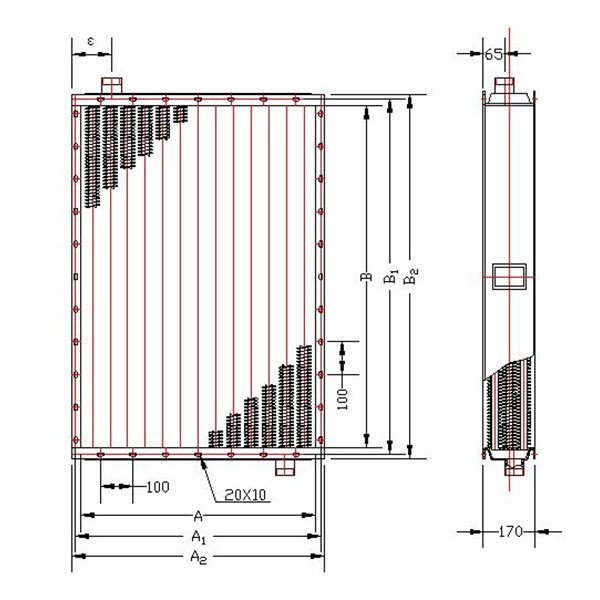

3.SRQ steam radiator specification description: SRQ ① × ② ③

①, ②-respectively, the radiator length, width size decimeter

③-Indicates the heat dissipation capacity of the radiator (large D, medium Z, small X)

Structural features of 2. SRQ steam radiator

1. The steam radiator adopts a fixed porous plate structure, and the heat dissipation pipes (three rows) are arranged in a fork row, with compact structure, good air tightness and easy installation.

2. The heat medium of the steam radiator flows through the radiator in the form of single return, with high heat exchange efficiency and fast heating speed.

3. The finned heat pipe of the steam radiator is made of Φ22 × 2 seamless steel pipe wound by a special machine with 0.5 × 16mm steel strip, which has good heat exchange effect, high pressure bearing and corrosion resistance.

4. The fin tube of the steam radiator is 5mm(D)6mm(Z)8mm(X) from the corresponding heat dissipation capacity.

5. The inlet and outlet interfaces of steam radiator are connected with threads on different sides.

Technical Parameters of 3. SRQ Steam Radiator

Model Heat dissipation area

(m2)heat medium Number of tube bundles Dimensions (mm) Connecting pipe

(inch)Weight

(kg)A B A1 B1 A2 B2 SRQ5× 5D 7.48 Steam

or

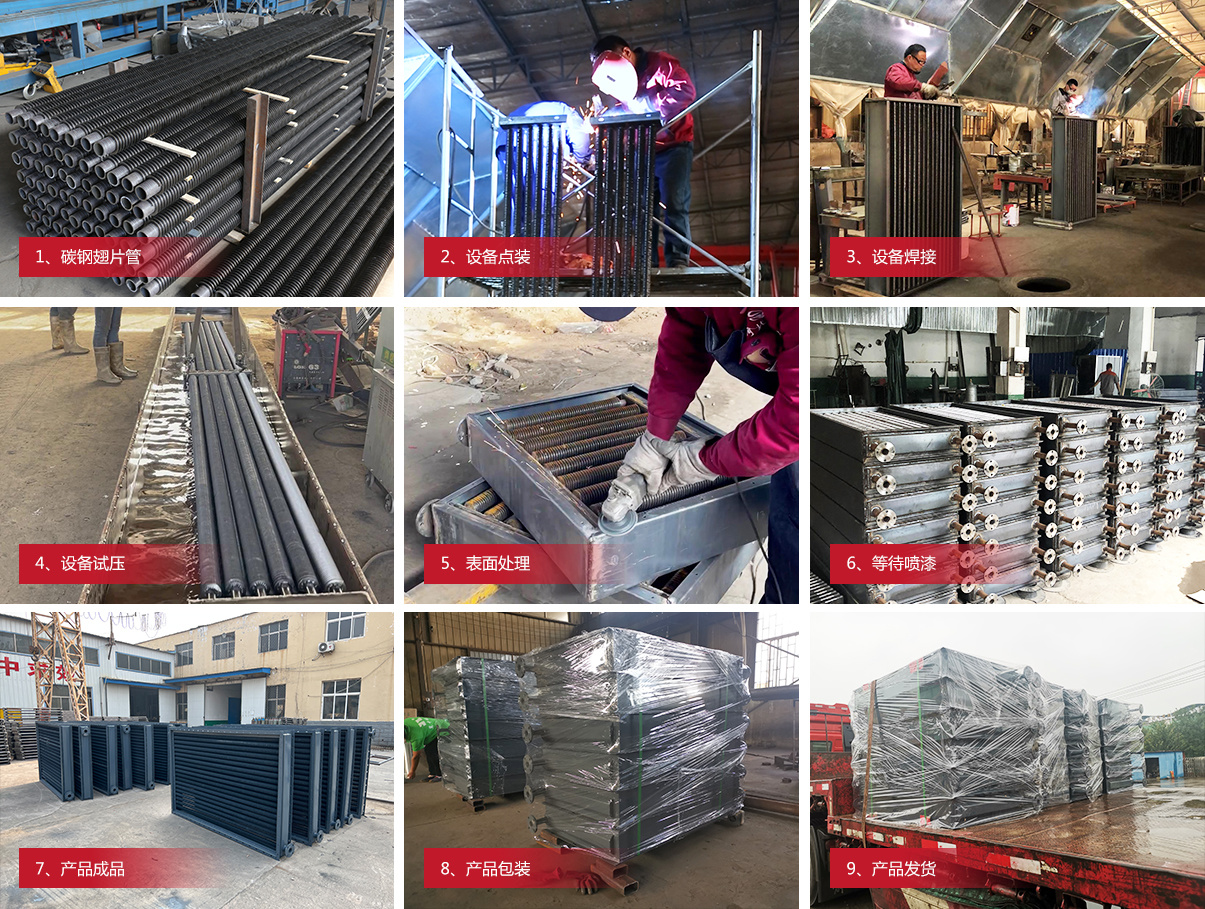

Hot water20 440 440 470 470 500 500 1 1/4" 41 SRQ6 × 5D 9.18 20 540 570 600 54 SRQ7× 5D 10.88 20 640 670 700 68 SRQ10 × 5D 15.98 20 940 970 1000 81 SRQ12 × 5D 19.38 20 1140 1170 1200 108 SRQ6 × 6D 11.94 26 540 540 570 570 600 600 1.5" 62 SRQ7× 6D 14.15 26 640 670 700 72 SRQ10 × 6D 20.78 26 940 970 1000 104 SRQ12 × 6D 25.20 26 1140 1170 1200 124 SRQ15 × 6D 31.83 26 1440 1470 1500 155 SRQ7× 7D 15.78 29 640 640 670 670 700 700 2.0" 80 SRQ10 × 7D 23.17 29 940 970 1000 114 SRQ12 × 7D 28.12 29 1140 1170 1200 137 SRQ15 × 7D 35.53 29 1440 1470 1500 172 SRQ17 × 7D 40.42 29 1640 1670 1700 194 SRQ10 × 10D 35.16 44 940 940 970 970 1000 1000 2.5" 140 SRQ12 × 10D 42.64 44 1140 1170 1200 185 SRQ15 × 10D 53.85 44 1440 1470 1500 227 SRQ17 × 10D 61.34 44 1640 1670 1700 262 SRQ20 × 10D 72.56 44 1940 1970 2000 310 Production process

: next page