Products

Focus on the research and development design of finned tube and finned tube equipment

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

SRQ steam radiator is composed of steel perforated plate frame and steel heat dissipation finned tube. It is widely used in air heating of drying system and large and medium-sized heating, ventilation and heat exchange system.

SLZ drying room radiator is composed of carbon steel frame fixed and steel pipe aluminum fin tube bundle; The finned tube adopts the steel tube aluminum fin binding process, which is smooth, free of burrs, wrinkle-free and easy to clean. It is easy to remove condensed water on the fin surface during wet cooling in heating and air conditioning engineering, and is not easy to form dust and scale in dry heating and other heat exchange occasions. The radiator has compact structure, good air tightness and convenient installation.

SLZ drying room radiator is composed of carbon steel frame fixed and steel pipe aluminum fin tube bundle; The finned tube adopts the steel tube aluminum fin binding process, which is smooth, free of burrs, wrinkle-free and easy to clean. It is easy to remove condensed water on the fin surface during wet cooling in heating and air conditioning engineering, and is not easy to form dust and scale in dry heating and other heat exchange occasions. The radiator has compact structure, good air tightness and convenient installation.

SLZ drying room radiator is composed of carbon steel frame fixed and steel pipe aluminum fin tube bundle; The finned tube adopts the steel tube aluminum fin binding process, which is smooth, free of burrs, wrinkle-free and easy to clean. It is easy to remove condensed water on the fin surface during wet cooling in heating and air conditioning engineering, and is not easy to form dust and scale in dry heating and other heat exchange occasions. The radiator has compact structure, good air tightness and convenient installation.

GL II industrial radiator adopts advanced technology, high heat transfer performance of seamless steel tube around the steel fin, by steel perforated plate frame support and finned tube composition;

GL II industrial radiator adopts advanced technology, high heat transfer performance of seamless steel tube around the steel fin, by steel perforated plate frame support and finned tube composition;

GL II industrial radiator adopts advanced technology, high heat transfer performance of seamless steel tube around the steel fin, by steel perforated plate frame support and finned tube composition;

The GL finned tube radiator is made of seamless steel tube rolled aluminum fins with advanced technology and high heat transfer performance, and is composed of steel perforated plate frame supporting steel and aluminum composite heat dissipation finned tubes;

The finned radiator is the most widely used heat exchanger in gas and liquid heat exchange equipment. It achieves the purpose of heat transfer enhancement by processing fins on ordinary base tubes. The base pipe can be made of steel pipe; stainless steel pipe; copper pipe, etc. Fins can also be used with steel strips; stainless steel strips; copper strips; aluminum strips, etc., which can be customized according to needs.

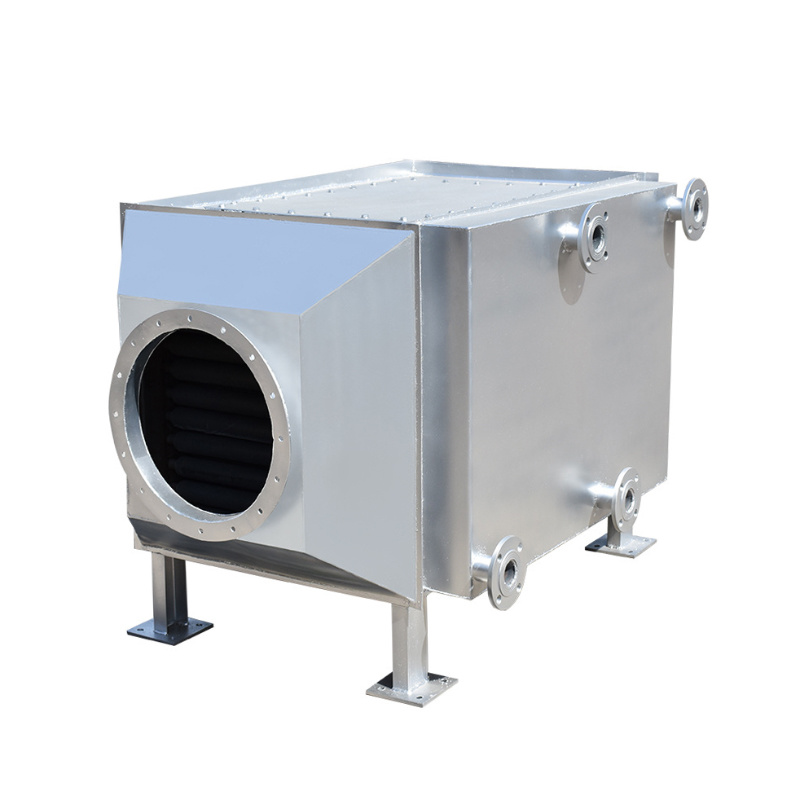

Boiler economizer is another name for waste heat recovery equipment. Because it is used in conjunction with boilers, it is sometimes called boiler economizer, but the working principle and composition of the equipment have not changed. Boiler economizer is an energy-saving device. The structure of the whole equipment is relatively simple. It is mainly composed of carbon steel, alloy steel or stainless steel metal plates. These plates will be arranged in a certain order.

Flue gas is the main way to waste energy in general energy-consuming equipment. For example, boiler exhaust energy consumption is about 15%, while other equipment such as setting machines, dryers and kilns in the printing and dyeing industry mainly consume energy through flue gas emissions. Flue gas waste heat recovery is mainly through a certain heat exchange method to convert the heat carried by the flue gas into the heat that can be used. The main ways of waste heat recovery are: flue gas waste heat recovery hot water, flue gas waste heat recovery air. Here focuses on flue gas waste heat recovery hot water.

Flue gas is the main way to waste energy in general energy-consuming equipment. For example, boiler exhaust energy consumption is about 15%, while other equipment such as setting machines, dryers and kilns in the printing and dyeing industry mainly consume energy through flue gas emissions. Flue gas waste heat recovery is mainly through a certain heat exchange method to convert the heat carried by the flue gas into the heat that can be used. The main ways of waste heat recovery are: flue gas waste heat recovery hot water, flue gas waste heat recovery air. Here focuses on flue gas waste heat recovery hot water.