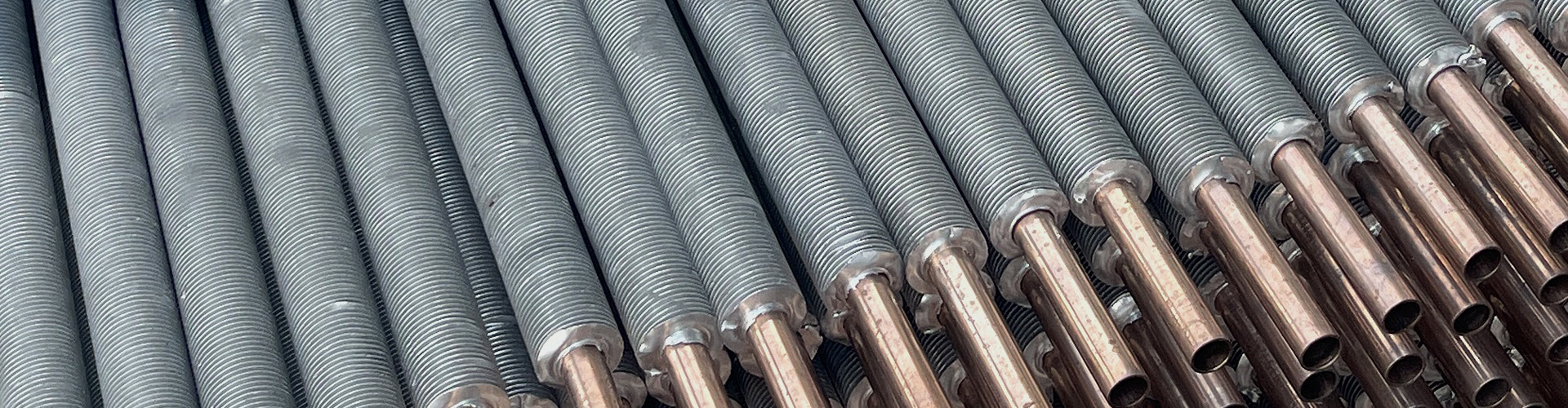

Bimetallic finned tube

Focus on the research and development design of finned tube and finned tube equipment

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

The rolled finned tube is formed by cold rolling of the pressure-resistant base tube and aluminum tube on a special machine tool, which overcomes the shortcomings that aluminum and other metals cannot be welded. It uses the pressure resistance of the base tube and the efficient heat transfer of aluminum. Plasticity, highlighting the characteristics of the two materials in the process.

The processing technology of copper-aluminum composite finned tube is first processed into a bimetallic composite tube by aluminum sheet and copper tube, and then mechanically cold-rolled. Using the physical characteristics of the aluminum tube, the copper tube is made as the core of the pipe, and the fin tube is closely combined with the cold-rolled aluminum fin.

The L-shaped winding process is to wind a strip-shaped thin metal strip onto a tube in a spiral shape along the transverse direction of the tube through a winding machine. This process is less, high production efficiency, saving materials, stable product quality.

LL type finned tube, the pipe is steel pipe or stainless steel pipe, the fin material is aluminum, and the working temperature can reach 180 degrees.

KL-type finned tube is also called knurled finned tube. Before winding the fin, the pattern is rolled on the base tube, or a blade is added to the winding machine to knurl on the base tube. The back blade is used for winding, knurling and winding at the same time.

The inlaid spiral finned tube is a spiral groove with a certain width and depth in advance on the steel pipe, and then the steel belt is inlaid on the steel pipe on the lathe. During the winding process, due to a certain pre-tightening force, the steel strip will be tightly tightened in the spiral groove, thereby ensuring a certain contact area between the steel strip and the steel pipe.