Gas-gas heat exchanger

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

Gas-gas heat exchanger

A gas-gas heat exchanger (also known as an air heat exchanger or heat exchanger) is a device used to transfer heat from one gaseous fluid to another. It is commonly used in applications of thermal energy recovery, energy conservation and temperature regulation. It is an energy-saving and environmental protection device for heat exchange between the original flue gas and the net flue gas. It is widely used in the fields of desulfurization, denitration and whitening, sulfur alkali washing, flue corrosion protection and so on.

- Product Description

-

Overview of 1. gas heat exchanger

A gas-gas heat exchanger (also known as an air heat exchanger or heat exchanger) is a device used to transfer heat from one gaseous fluid to another. It is commonly used in applications of thermal energy recovery, energy conservation and temperature regulation. It is an energy-saving and environmental protection device for heat exchange between the original flue gas and the net flue gas. It is widely used in the fields of desulfurization, denitration and whitening, sulfur alkali washing, flue corrosion protection and so on.

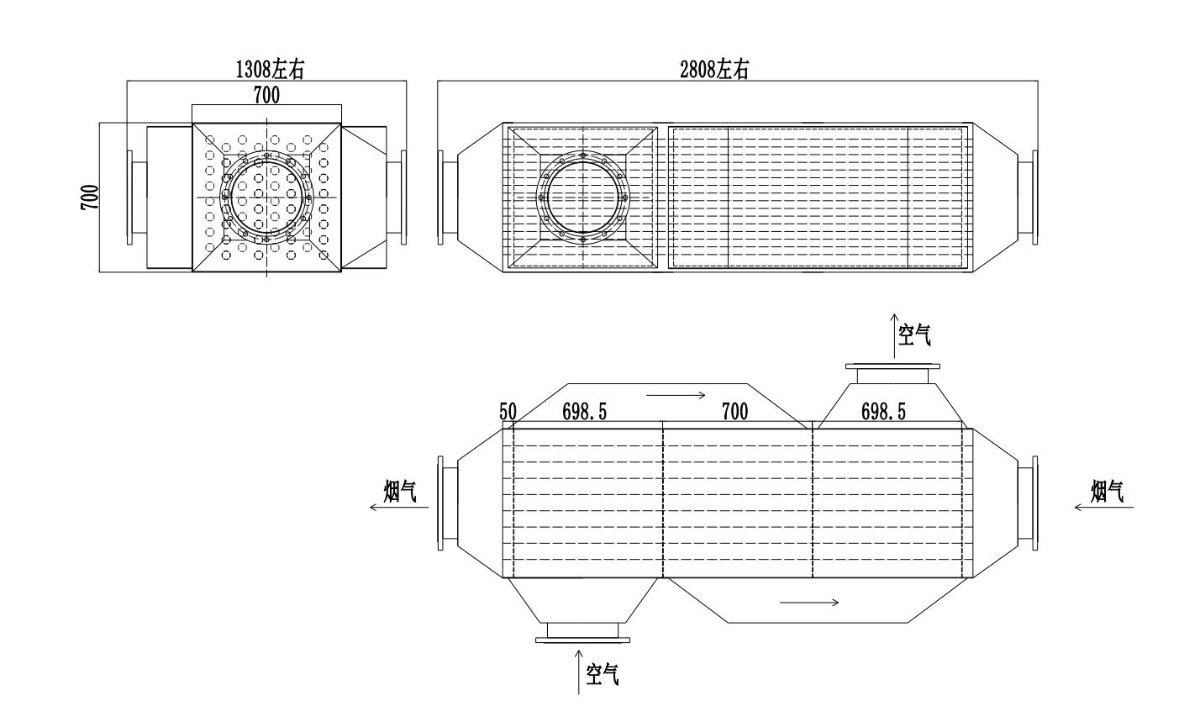

Basic composition of 2. gas heat exchanger

1. Heat exchanger core: The core of a heat exchanger is a structure composed of a series of tubes or plates that allow two gas fluids to cross flow in it, thereby achieving heat transfer.

2. Inlet and outlet: The heat exchanger usually has two side ports, one for the hot gas fluid entering the heat exchanger, and the other for the heated gas fluid output.

3. Shell: The shell is the outer shell of the heat exchanger, which is used to surround and protect the core of the heat exchanger. It usually has thermal insulation or insulation to reduce heat loss.

4. Fans or air ducts: Some gas-gas heat exchanger systems may include fans or air ducts to push the gas fluid through the heat exchanger to increase heat exchange efficiency.

Characteristics of 3. gas heat exchanger

1. Efficient heat transfer: Gas-gas heat exchangers are designed to maximize heat transfer efficiency. The structure of the heat exchanger core is usually designed to have a large surface area to increase the possibility of heat exchange.

2. Energy saving: By recovering heat from waste heat gas and transferring it to the gas that needs to be heated, the gas-gas heat exchanger helps to save energy. This is especially important in industrial processes.

3. Environmental protection: The use of gas-gas heat exchangers can reduce energy consumption, reduce greenhouse gas emissions, and contribute to environmental protection.

4. Multiple applications: Gas-gas heat exchangers can be applied to a variety of scenarios, including heating, ventilation, air conditioning, waste heat recovery in industrial processes, condensation and vaporization in chemical processes, etc.

5. Suitable for different gases: Gas-gas heat exchangers can usually handle different types of gases, including gas, steam, air, exhaust gas, etc.

6. Maintenance and cleaning: Maintenance is relatively simple, usually only the surface of the heat exchanger core needs to be cleaned regularly to ensure heat transfer efficiency.

In short, the gas-gas heat exchanger is a device widely used in industrial and commercial applications for heat transfer and energy recovery. Its high efficiency and environmental characteristics make it an important part of many engineering projects.

Installation position of 4. gas heat exchanger

1. The gas-gas heat exchanger is mainly arranged in front of the electrostatic precipitator to reduce the flue gas temperature below the flue gas acid dew point, and then the heat is used to heat the flue gas in front of the chimney to increase the exhaust gas temperature. According to the different heat exchanger structures, it can be divided into separate closed flue gas-flue gas heat exchanger and rotary reheat flue gas-flue gas heat exchanger.

2, according to the different low temperature section gas heat exchanger layout position can be divided into flue gas cooler and flue gas reheater. The flue gas cooler is arranged after the air preheater, before the electrostatic precipitator, or between the precipitator and the desulfurization tower, using the waste heat of the boiler exhaust gas to heat condensate water, circulating water or other working conditions to reduce the exhaust gas temperature;

3. The flue gas reheater is arranged after the desulfurization tower and before the chimney, and uses circulating water that absorbs heat in the flue gas cooler or other working conditions to heat the net flue gas after the wet desulfurization device.

Of course, its location will also change according to the different working conditions of the industry. The location of the above gas-gas heat exchanger is explained according to the customers of the previously installed coal-fired power plant. The specifications of the gas heat exchanger are not fixed, and are designed and customized according to different working conditions.

Production process

Company Profile

The company's main products include fin tubes, fin tube radiators, fin tube heat exchangers, heaters, air preheaters, air coolers, etc. Product materials include steel, stainless steel, steel-aluminum composite, etc., and are widely used in chemical, petroleum, power, electric power, food, textile, printing and dyeing and other industries. The company strives for survival by quality, seeks benefits from management, takes scientific and technological innovation as the driving force for development, regards integrity as the foundation of the enterprise, and establishes a customer-centered business philosophy. Our products cover nearly 30 provinces, cities, and autonomous regions in China, and we have established long-term cooperative relationships with many of the top 500 companies in the country.

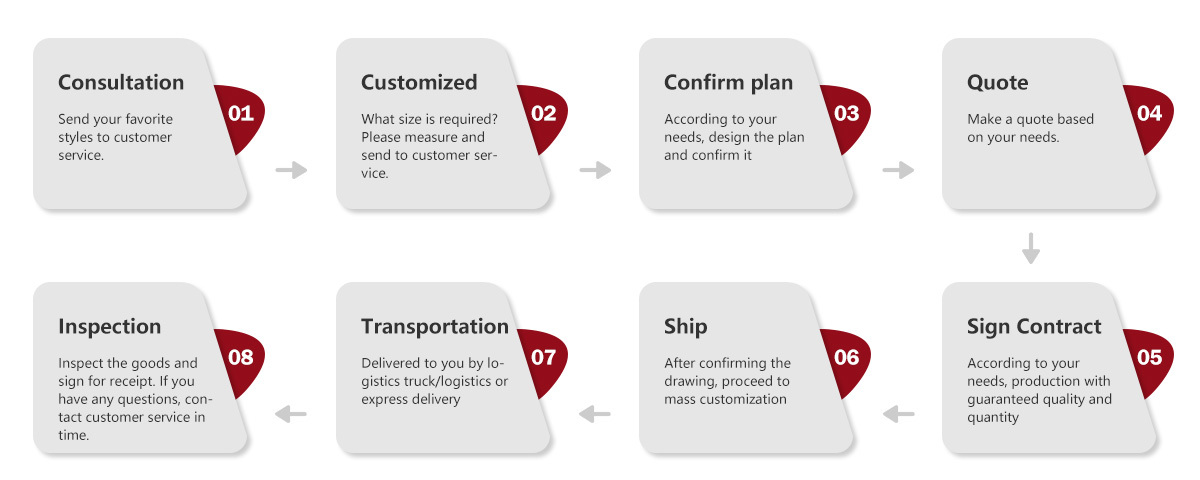

Personalized Customization Process

Product specifications and models, support processing customization

Partner

Qualification

Key words:

Get Quote

Related Products