Alloy steel heat exchanger

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

Alloy steel heat exchanger

Alloy steel finned tube heat exchanger is an efficient and reliable heat exchange equipment, is a new type of heat exchanger, with compact structure, high thermal efficiency, light weight, high compressive strength. The equipment is formed by adding a finned tube structure, because the finned tube surface has a large number of fins, can increase the contact area between the tube and the airflow, to achieve the purpose of improving heat exchange efficiency.

- Product Description

-

Overview of 1. alloy steel finned tube heat exchanger

Alloy steel finned tube heat exchanger is an efficient and reliable heat exchange equipment, is a new type of heat exchanger, with compact structure, high thermal efficiency, light weight, high compressive strength. The equipment is formed by adding a finned tube structure, because the finned tube surface has a large number of fins, can increase the contact area between the tube and the airflow, to achieve the purpose of improving heat exchange efficiency. It uses high-frequency welding technology to tightly weld the fins and the base tube together, thereby enhancing the heat transfer performance and heat dissipation area of the heat exchanger. The base tube of this heat exchanger is usually made of high-quality low-carbon steel or stainless steel, which has high corrosion resistance and mechanical strength. The fins are made of steel strips and are welded at high frequency to form a tight heat transfer unit with the base tube.

Advantages of 2. alloy steel finned tube heat exchanger

The advantages of alloy steel finned tube heat exchanger are its efficient heat transfer performance and large heat dissipation area. Because the welding between the fin and the base tube is realized by high-frequency welding technology, the weld quality is high, firm and reliable, and the stability and service life of the heat exchanger are ensured. In addition, this heat exchanger also has a low resistance coefficient and good ventilation performance, which can effectively reduce the resistance of air flow and improve the heat exchange efficiency.

Application of 3. Alloy Steel Finned Tube Heat Exchanger

It is widely used in various industrial fields and various systems that need heating. For example, in the petrochemical industry, it can be used in heater equipment. In addition, due to its efficient heat transfer performance and large heat dissipation area, it is also widely used in electric power, metallurgy, construction and other fields. In short, the steel high-frequency welded finned tube heat exchanger is an efficient and reliable heat exchange equipment, and has a wide range of applications. Its advantages are its efficient heat transfer performance, large heat dissipation area, low resistance coefficient and good ventilation performance. At the same time, it also has high corrosion resistance and mechanical strength, which can ensure the stability and reliability of long-term use.

Production process

Company Profile

The company's main products include fin tubes, fin tube radiators, fin tube heat exchangers, heaters, air preheaters, air coolers, etc. Product materials include steel, stainless steel, steel-aluminum composite, etc., and are widely used in chemical, petroleum, power, electric power, food, textile, printing and dyeing and other industries. The company strives for survival by quality, seeks benefits from management, takes scientific and technological innovation as the driving force for development, regards integrity as the foundation of the enterprise, and establishes a customer-centered business philosophy. Our products cover nearly 30 provinces, cities, and autonomous regions in China, and we have established long-term cooperative relationships with many of the top 500 companies in the country.

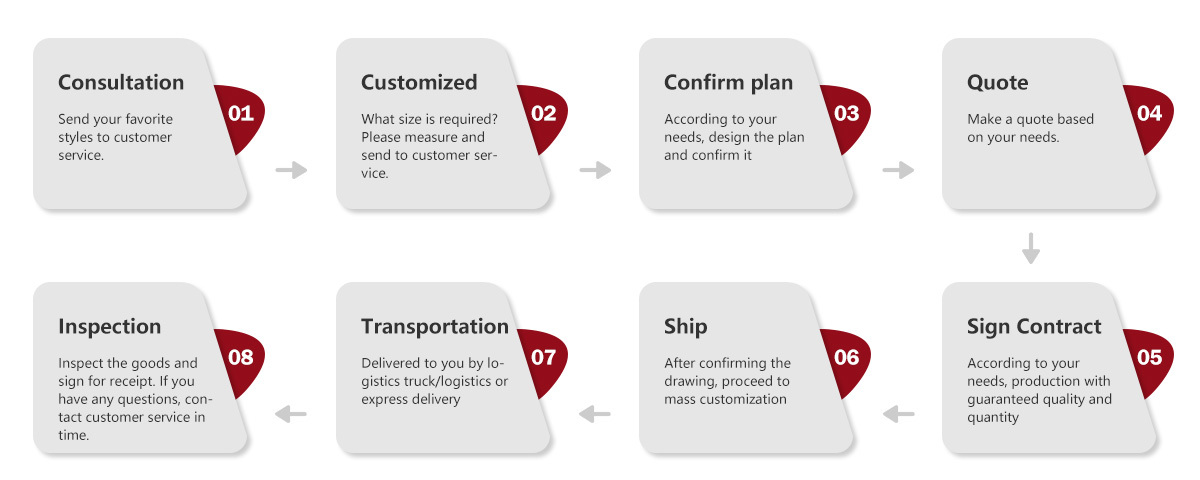

Personalized Customization Process

Product specifications and models, support processing customization

Partner

Qualification

Key words:

Get Quote

Related Products