Waste heat recovery heat exchanger

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

Waste heat recovery heat exchanger

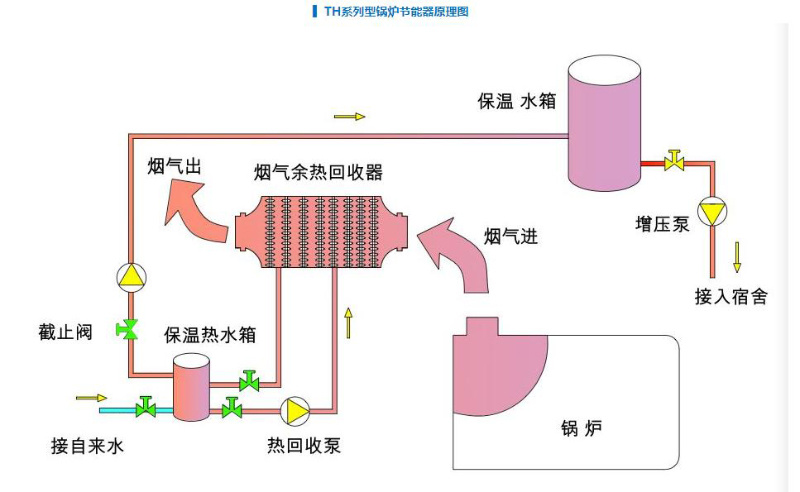

Flue gas is the main way to waste energy in general energy-consuming equipment. For example, boiler exhaust energy consumption is about 15%, while other equipment such as setting machines, dryers and kilns in the printing and dyeing industry mainly consume energy through flue gas emissions. Flue gas waste heat recovery is mainly through a certain heat exchange method to convert the heat carried by the flue gas into the heat that can be used. The main ways of waste heat recovery are: flue gas waste heat recovery hot water, flue gas waste heat recovery air. Here focuses on flue gas waste heat recovery hot water.

- Product Description

-

Overview of 1. Heat Recovery Heat Exchanger

Flue gas is the main way to waste energy in general energy-consuming equipment. For example, boiler exhaust energy consumption is about 15%, while other equipment such as setting machines, dryers and kilns in the printing and dyeing industry mainly consume energy through flue gas emissions. Flue gas waste heat recovery is mainly through a certain heat exchange method to convert the heat carried by the flue gas into the heat that can be used. The main ways of waste heat recovery are: flue gas waste heat recovery hot water, flue gas waste heat recovery air. Here focuses on flue gas waste heat recovery hot water.

The heat exchange components in the flue gas waste heat recovery hot water heat exchanger mainly include high-frequency welded spiral finned tube, steel-aluminum composite finned tube, stainless steel-aluminum composite finned tube, all stainless steel finned tube and other combinations. The steel-aluminum composite finned tube extruded by the aluminum tube reduces the heat transfer thermal resistance and high temperature resistance. In order to prevent ash blocking and corrosion, the flue gas temperature at the outlet of the waste heat recovery device is generally controlled above the dew point, I .e. the flue gas temperature of oil-fired and coal-fired boilers is ≤ 130 ℃, and the flue gas temperature of gas-fired boilers is ≤ 100 ℃, saving 4-18% of fuel.

Characteristics of 2. waste heat recovery heat exchanger

1. High heat transfer performance. Especially for gas-water heat recovery heat exchanger, it can show its advantages.

2. The average temperature difference of heat transfer is large. The channel arrangement of cold and hot fluids is convenient, and the flow direction can be arranged in a simple countercurrent form.

3. Compact structure. Since the fins are added to the tubes to increase the heat dissipation area, the heat transfer capacity of each heat exchange tube is also large, and the number of heat exchange tubes can be used to ensure heat transfer.

4. Flexible layout. The heat exchange tube can be used as a general heat transfer element and can be combined arbitrarily by changing the number of heat exchange tubes.

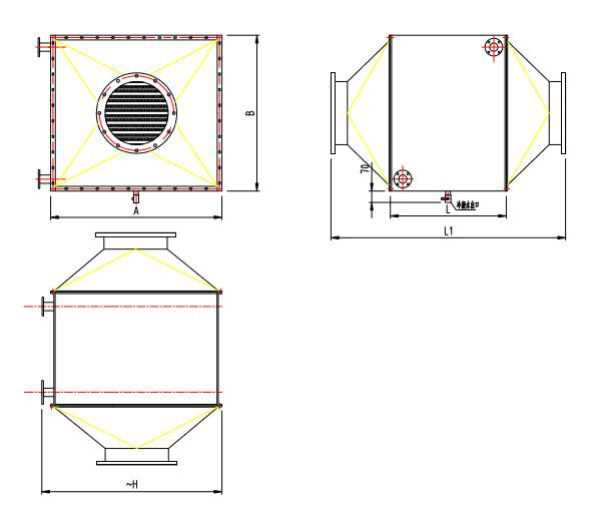

Outline Structure Dimension Drawing of 3. Waste Heat Recovery Heat Exchanger

Installation of 4. waste heat recovery heat exchanger

1. Before installing the waste heat recovery heat exchanger, first check the appearance for damage. During installation, ensure that each waste heat recovery heat exchanger is hoisted in place and positioned accurately.

2. As a part of the air duct, the shell of the waste heat recovery heat exchanger is usually connected with the air duct through a reducing flange. The shell frame of the waste heat recovery heat exchanger has a flange hole that can be connected with the air duct, and the middle of the flange is equipped with a sealing gasket and bolts. Special cases can also be used in the form of non-removable welding.

3. Pay attention to the direction of the inlet and outlet during installation. The inlet and outlet of the waste heat recovery heat exchanger shall be low and high. It is recommended to install valves and instruments such as stop valves, pressure gauges and thermometers at the inlet and outlet. When automatic control is required, an electric control valve shall be installed at the inlet.

4. After installation, it must be hydrostatically tested, and the test pressure shall refer to GB/T 14296-2008 air cooler and air heater standard.

Operation of heat exchanger for 5. waste heat recovery

When the waste heat recovery heat exchanger is deactivated, the air side valve must be closed first, then the water inlet valve must be closed, and the drain valve through the trench must be opened to drain the accumulated water in the heat exchange tube and header of the waste heat recovery economizer, which can be maintained with full water even if it is not used for a long time. When starting, slowly open the water inlet valve to feed cold water. After the opening of the water inlet valve is fully opened and the heat exchange tube of the waste heat recovery heat exchanger is completely filled with water, then open the air side valve to feed high-temperature gas. Special personnel are not required for special monitoring during normal operation.

Production process

Company Profile

The company's main products include fin tubes, fin tube radiators, fin tube heat exchangers, heaters, air preheaters, air coolers, etc. Product materials include steel, stainless steel, steel-aluminum composite, etc., and are widely used in chemical, petroleum, power, electric power, food, textile, printing and dyeing and other industries. The company strives for survival by quality, seeks benefits from management, takes scientific and technological innovation as the driving force for development, regards integrity as the foundation of the enterprise, and establishes a customer-centered business philosophy. Our products cover nearly 30 provinces, cities, and autonomous regions in China, and we have established long-term cooperative relationships with many of the top 500 companies in the country.

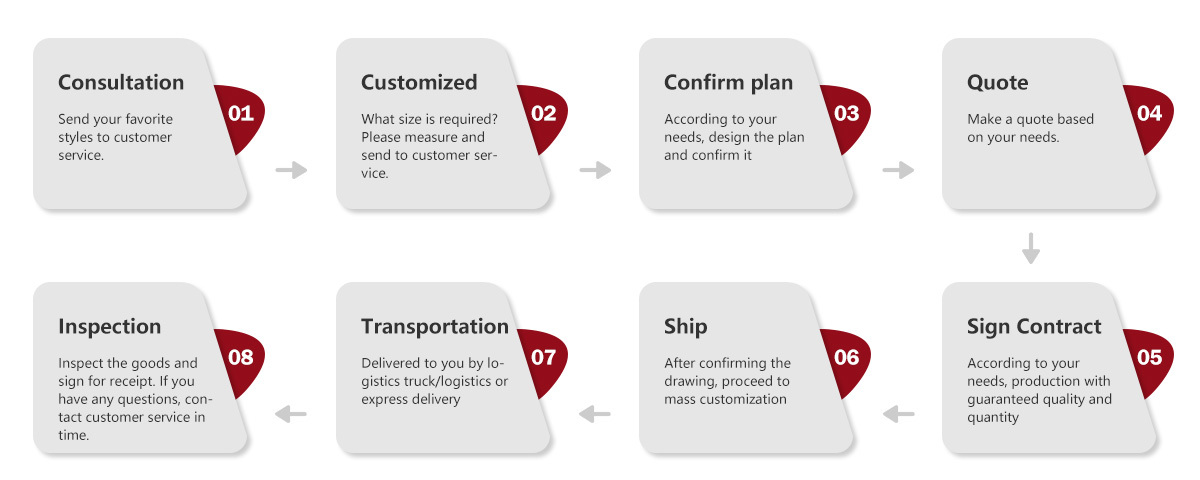

Personalized Customization Process

Product specifications and models, support processing customization

Partner

Qualification

Key words:

Get Quote

Related Products