Carbon steel heat exchanger

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

Carbon steel heat exchanger

Carbon steel finned tube heat exchanger is a kind of high efficient heat exchange equipment which is widely used in chemical, petroleum, electric power, metallurgy and other fields. Its main feature is the use of carbon steel finned tube as a heat transfer element, with good corrosion resistance and high cost performance.

- Product Description

-

Overview of 1. Carbon Steel Heat Exchanger

Carbon steel finned tube heat exchanger is a kind of high efficient heat exchange equipment which is widely used in chemical, petroleum, electric power, metallurgy and other fields. Its main feature is the use of carbon steel finned tube as a heat transfer element, with good corrosion resistance and high cost performance.

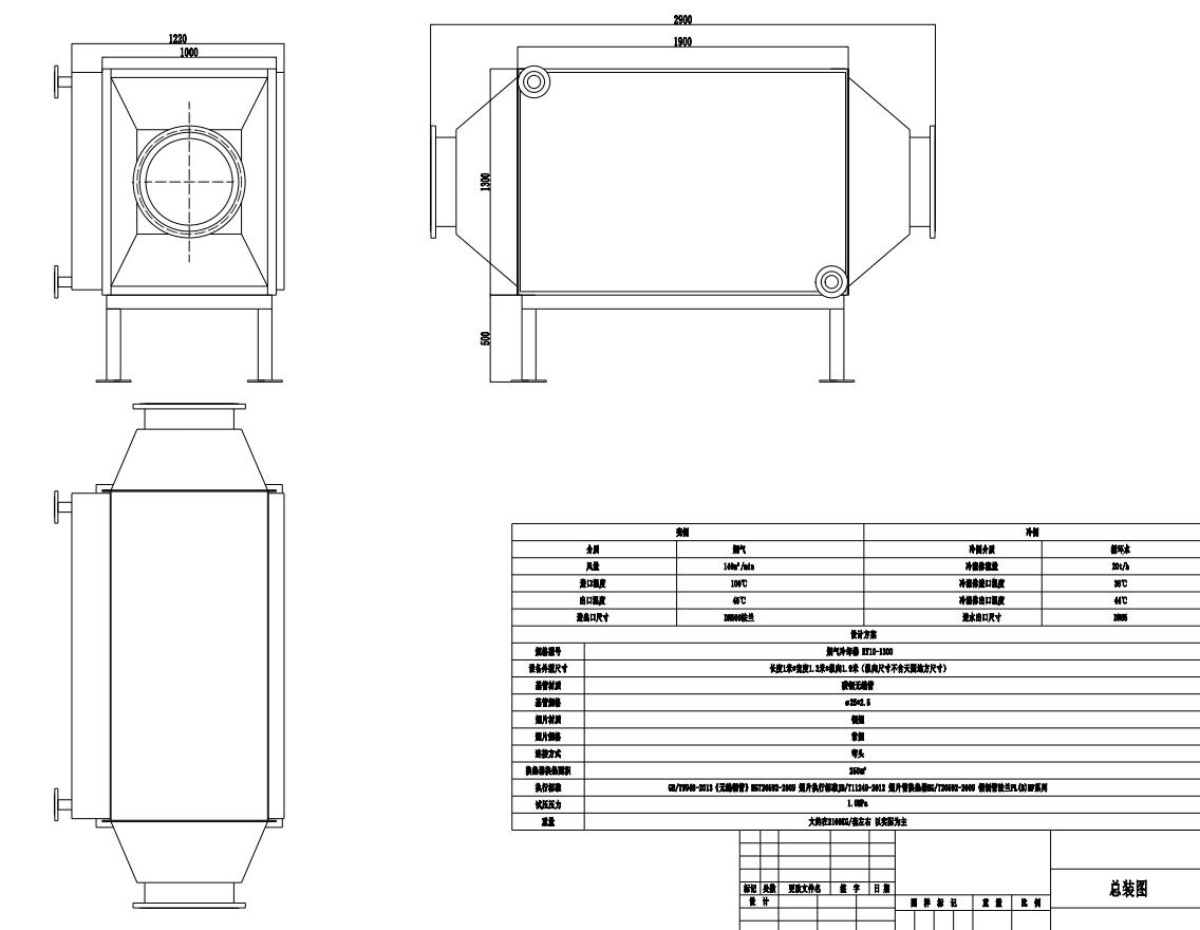

Structure and Principle of 2. Carbon Steel Heat Exchanger

Carbon steel finned tube heat exchanger is usually composed of shell, tube plate, carbon steel finned tube bundle, head and other parts. When working, two kinds of fluids with different temperatures pass through the inner and outer sides of the finned tube respectively. Due to the existence of the fins, the heat exchange area is increased, thereby improving the heat exchange efficiency.

Material Characteristics and Advantages of 3. Carbon Steel Heat Exchanger

Carbon steel: Carbon steel is the main material for making finned tubes. It has excellent thermal conductivity and mechanical strength. At the same time, the price is relatively low and it is easy to process.

Anti-corrosion treatment: Although the corrosion resistance of carbon steel itself is not as good as that of special metal materials such as stainless steel, anti-corrosion treatment can be carried out by surface spraying or coating to improve its service life in specific environments.

Advantages: Carbon steel finned tube heat exchanger has the advantages of low cost, simple maintenance and wide range of use.

4. carbon steel heat exchanger fin form

At present, the carbon steel finned tubes on the market mainly have the following types:

Winding fin tube: A fin is formed by continuously winding a strip of metal around a base tube.

Tandem fin tube: a single fin is made in advance, and then it is successively penetrated into the base tube and fixed.

High-frequency welding finned tube: the heat generated by high-frequency current is used to melt the fins and the base tube locally, and then the effect of close connection is achieved after cooling.

Spiral finned tube: A spiral shaped fin is produced on the base tube by a rolling or extrusion process.

5. carbon steel heat exchanger application field

Because the carbon steel finned tube heat exchanger has the characteristics of low cost, light weight, convenient installation and maintenance, it is widely used in various heating and cooling processes in industrial production, such as air preheater, waste heat recovery system, condenser, Evaporator, etc.

6. Carbon Steel Tube Heat Exchanger Design Considerations

The nature of the heat exchange medium: including physical state (gas, liquid), chemical composition, pressure, temperature, etc., these parameters will affect the selection and arrangement of the finned tube.

Flow and temperature difference: Determine the required heat exchange area according to actual operating conditions, and ensure sufficient temperature difference to achieve effective heat transfer.

Space constraints: While meeting heat exchange needs, the size and layout of the equipment need to be considered to facilitate on-site installation and maintenance.

Economy: Under the premise of ensuring performance, reduce the investment and operating costs of equipment as much as possible.

Production process

Company Profile

The company's main products include fin tubes, fin tube radiators, fin tube heat exchangers, heaters, air preheaters, air coolers, etc. Product materials include steel, stainless steel, steel-aluminum composite, etc., and are widely used in chemical, petroleum, power, electric power, food, textile, printing and dyeing and other industries. The company strives for survival by quality, seeks benefits from management, takes scientific and technological innovation as the driving force for development, regards integrity as the foundation of the enterprise, and establishes a customer-centered business philosophy. Our products cover nearly 30 provinces, cities, and autonomous regions in China, and we have established long-term cooperative relationships with many of the top 500 companies in the country.

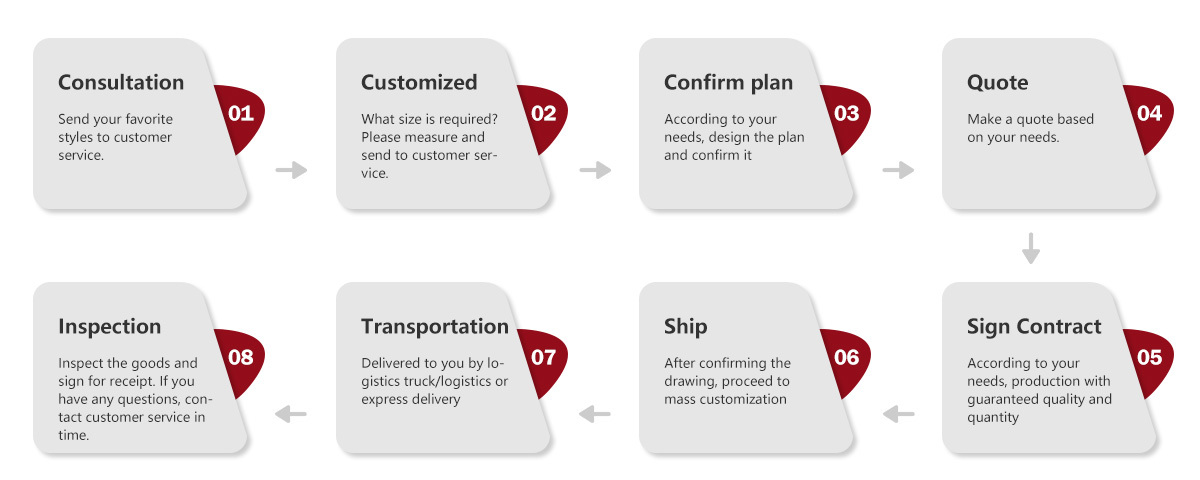

Personalized Customization Process

Product specifications and models, support processing customization

Partner

Qualification

Key words:

Get Quote

Related Products