Air preheater

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

Air preheater

Air preheater is the boiler tail flue gas through the internal fins will enter the boiler before the air preheated to a certain temperature of the heating surface, is a kind of used to improve the heat exchange performance of the boiler, reduce energy consumption equipment. Air preheater is also referred to as air preheater, is to improve the boiler heat exchange performance, reduce heat loss of a preheating equipment. The function of the air preheater is to conduct the heat carried in the flue gas discharged from the boiler tail flue to the air before entering the boiler through the heat sink, and preheat the air to a certain temperature. Is a gas-gas type heat exchange equipment, the use of flue gas heating air, widely used in nitrogen fertilizer industry gas section, blowing gas latent heat recovery system and boiler, petroleum, metallurgy and other industries of waste heat recovery and utilization.

- Product Description

-

Overview of 1. air preheater

Air preheater is the boiler tail flue gas through the internal fins will enter the boiler before the air preheated to a certain temperature of the heating surface, is a kind of used to improve the heat exchange performance of the boiler, reduce energy consumption equipment. Air preheater is also referred to as air preheater, is to improve the boiler heat exchange performance, reduce heat loss of a preheating equipment. The function of the air preheater is to conduct the heat carried in the flue gas discharged from the boiler tail flue to the air before entering the boiler through the heat sink, and preheat the air to a certain temperature. Is a gas-gas type heat exchange equipment, the use of flue gas heating air, widely used in nitrogen fertilizer industry gas section, blowing gas latent heat recovery system and boiler, petroleum, metallurgy and other industries of waste heat recovery and utilization.

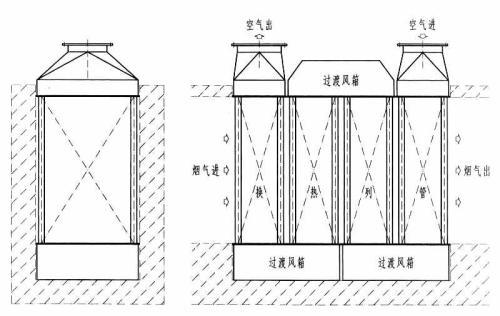

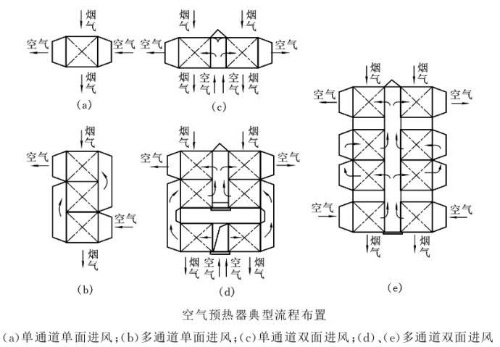

Equipment Structure and Working Principle of 2. Air Preheater

The product consists of three parts: heat pipe, tube sheet and shell. When working, the air passes through the upper side of the tube plate, the flue gas passes through the lower side of the tube plate, and the heat exchange is carried out by the phase change of the working medium in the heat pipe, thus completing the whole heat exchange process.

According to the heat transfer mode of the air preheater, the air preheater can be divided into two categories: heat conduction type and regeneration type. The most commonly used in the heat-conducting air preheater is the tubular air preheater. With the improvement of boiler parameters and the increase of capacity, the heating surface of tubular air preheater also increases, which brings difficulties to the layout of the tail heating surface. Therefore, the majority of large capacity units in the use of compact, light weight rotary air preheater.

3. air preheater function

1. Improve and strengthen the combustion. The air after the waste heat device enters the furnace, which accelerates the drying, ignition and combustion process of the fuel, ensures the stable combustion in the boiler, and improves the combustion efficiency.

2, enhanced heat transfer due to the furnace combustion has been improved and strengthened, coupled with the hot air temperature into the furnace, the average temperature level of the furnace has also increased, which can strengthen the furnace radiation heat transfer.

3, reduce the furnace loss, reduce the exhaust temperature, improve the thermal efficiency of the boiler due to the furnace combustion stability, radiation heat exchange enhancement, can reduce the chemical incomplete combustion loss; on the other hand, the air preheater use flue gas waste heat, further reduce the exhaust loss, thus improving the thermal efficiency of the boiler. According to experience, when the air in the preheater rises 1.5 ℃, the exhaust gas temperature can be reduced by 1 ℃. After the air preheater is installed in the boiler flue, if the air waste heat can be 150-160 ℃, the exhaust gas temperature can be reduced by 110-120 ℃, and the thermal efficiency of the boiler can be increased by 7%-7.5. Can save fuel 11%-12%.

4. Hot air can be used as fuel desiccant. For layer-fired furnaces, hot air can use fuel with high moisture and ash content. For power station boilers, hot air is an important desiccant and pulverized coal conveying medium for pulverizing system.

Production process

Company Profile

The company's main products include fin tubes, fin tube radiators, fin tube heat exchangers, heaters, air preheaters, air coolers, etc. Product materials include steel, stainless steel, steel-aluminum composite, etc., and are widely used in chemical, petroleum, power, electric power, food, textile, printing and dyeing and other industries. The company strives for survival by quality, seeks benefits from management, takes scientific and technological innovation as the driving force for development, regards integrity as the foundation of the enterprise, and establishes a customer-centered business philosophy. Our products cover nearly 30 provinces, cities, and autonomous regions in China, and we have established long-term cooperative relationships with many of the top 500 companies in the country.

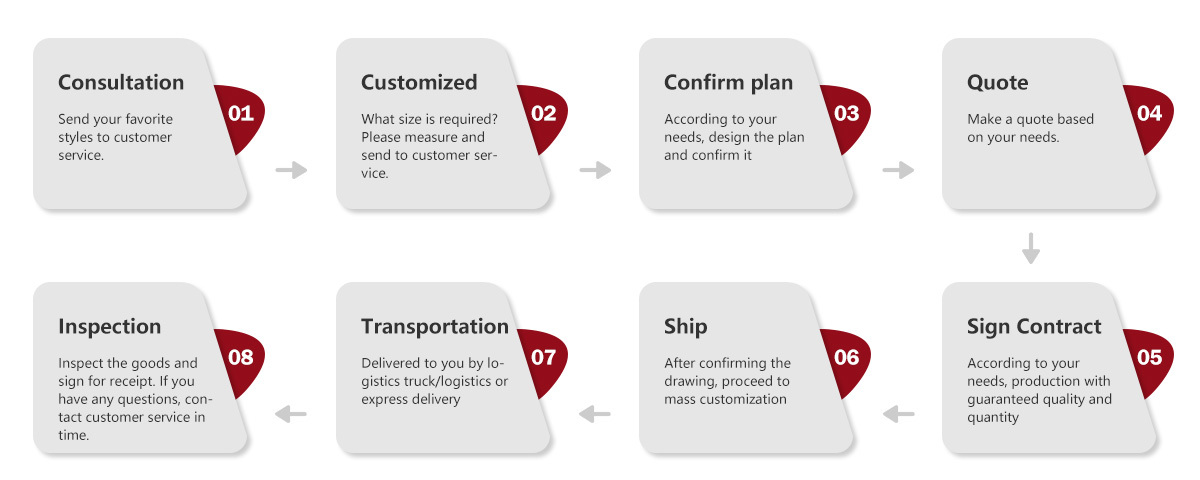

Personalized Customization Process

Product specifications and models, support processing customization

Partner

Qualification

Key words:

Get Quote

Related Products