Bimetallic finned tube

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

L-shaped finned tube

The L-shaped winding process is to wind a strip-shaped thin metal strip onto a tube in a spiral shape along the transverse direction of the tube through a winding machine. This process is less, high production efficiency, saving materials, stable product quality.

- Product Description

-

1. Overview

The L-shaped winding process is to wind a strip-shaped thin metal strip onto a tube in a spiral shape along the transverse direction of the tube through a winding machine. This process is less, high production efficiency, saving materials, stable product quality.

2. production process

For the L-shaped finned tube, the metal thin strip is pressed into an L-shape (the length of the short side is equal to the fin spacing, and the long side is equal to the fin height) on the winding machine, and then the short side is tightly wrapped and pressed on the surface of the tube through the Kun wheel mechanism. This process is widely used at home and abroad.

Pipe material is not limited, carbon steel pipe, stainless steel pipe, copper pipe, aluminum pipe can be. But the fins can only use steel, aluminum and other good ductility, high tensile strength of metal.

Characteristic parameters of domestic L type finned tube:

1. Base tube diameter: At present, the base tube diameter of finned tube has various sizes, the approximate range is 1/4 inch to 1 inch for non-ferrous metals; The steel pipe is 1/2 inch to 4 inches. But it's used on the air cooler.

There are only 1 inch, 1 1/4 inch and 1 1/2 inch. Among them, 1 inch steel pipe is the most common, generally larger for viscous media. Under the premise of meeting the fluid pressure drop in the tube, the diameter of the base tube should be selected as small as possible, which is conducive to heat transfer.

2. Pipe wall thickness: The wall thickness of the base pipe is mainly determined according to factors such as pressure, rigidity, corrosion, and material. Generally should not be less than 2mm.

3. Fin height: The higher the fin, the larger the heat transfer area, but the heat transfer efficiency of the fin decreases. Within a certain height, the effective area, fin efficiency, increases faster, and the effective area increases little beyond this height. Therefore, the fin height should have an optimal value.

3. features

a. Maximum operating temperature ≤ 150°C

B. Maximum service pressure ≤ 32MPa

c. Advantages: The finned tube adopts winding process, which has high production efficiency, uniform sheet distance, good heat transfer, high fin ratio, low price and wide use.

d. Disadvantages: 1. Poor thermal shock performance, not easy to be used in occasions with large vibration; 2. Not easy to use on wet air coolers.

4. Application Areas

Application: Mainly used in petrochemical, electric power, paper, tobacco, building heating and other industries of air coolers, air heaters and food industry drying system air heaters.

Table 2 Specifications of Common Heat Exchange Components

Finned tube category Base pipe Fin material finned tube Remarks Materials Diameter (mm) Pitch (mm) Sheet height (mm) Post-processing L-type finned tube (L) Steel Aluminum 25,32,38 Aluminum 2.3,2.5,2.8,3.2,3.6 12.5,16 1. The sheet height data of oval tube sleeve fin sleeve tube and plate fin sleeve tube are fin external dimensions.

2. Each plate fin sleeve tube passes through 60 tubes.

3. The base pipe is carbon steel, and stainless steel, chromium molybdenum steel, titanium pipe, etc. can also be selected according to the medium for users to choose.Double L-shaped finned tube (LL) Steel Knurled finned tube (KL) Inlaid finned tube (G) Bimetallic Rolled Tube (DR) Steel 2.3-3.0 8-16 Wash white Table 3 Different specifications of finned tube fin ratio table

Finned tube type Base pipe diameter mm Finned tube diameter (fin height) mm Wing ratio Fin spacing mm 2.3 2.5 2.8 3.2 3.6 Winding tube (l) 25 50(12.5) 16.91202 15.48172 14.01474 12.58444 11.15413 57(16) 23.39836 21.38383 19.31766 17.30314 15.28862 32 57(12.5) 15.72346 14.39958 13.04175 11.71787 10.39399 64(16) 21.45394 19.61392 17.72672 15.88670 14.04668 38 63(12.5) 15.05322 13.78935 12.49307 11.22921 9.96534 70(16) 20.35747 18.61585 16.82957 15.08796 13.34634 Double L-wound tube (LL) 25 50(12.5) 16.57545 15.17834 13.74541 12.3483l 10.95120 57(16) 23.06179 21.08046 19.04833 17.06701 15.08568 32 57(12.5) 15.38474 14.09362 12.76939 11.47827 10.18715 64(16) 21.11522 19.30796 17.45436 15.647l0 13.83984 38 63(12.5) 14.71328 13.48193 12.21900 10.98765 9.75629 70(16) 20.01753 18.30843 16.55550 14,84640 13.13730 Insert tube (G) 25 50(12.5) 17.23750 15.77500 14.27500 12.81250 11.35000 57(16) 23.72384 21.67712 19.57792 1 7.53120 15.48448 32 50(12.5) 16.05352 14.69766 13.30703 11.95117 10.59531 64 (16) 21.78400 19.91200 17.99200 16.12000 14.24800 38 63(12.5) 15.38585 14.099013 12.76118 11.46546 10.16974 70(16) 20.69011 18.91663 17.09768 15.32421 13.54462 Bimetallic Rolled Tube (DR) 25 50(12.5) 16.40300 15.02287 13.60735 12.22722 10.84709 57(16) 22.88935 20.92499 18.91027 16.94592 14.98157 32 50(12.5) 15.21213 13.93768 12.63056 11.35611 10.08166 64 (16) 20.94261 19.15203 17.31553 15.52494 13.73435 38 63(12.5) 14.54058 13.32573 12.07973 10.86488 9.65003 70(16) 19.84483 18.15223 16.41623 14.72363 13.03103

Company Profile

The company's main products include fin tubes, fin tube radiators, fin tube heat exchangers, heaters, air preheaters, air coolers, etc. Product materials include steel, stainless steel, steel-aluminum composite, etc., and are widely used in chemical, petroleum, power, electric power, food, textile, printing and dyeing and other industries. The company strives for survival by quality, seeks benefits from management, takes scientific and technological innovation as the driving force for development, regards integrity as the foundation of the enterprise, and establishes a customer-centered business philosophy. Our products cover nearly 30 provinces, cities, and autonomous regions in China, and we have established long-term cooperative relationships with many of the top 500 companies in the country.

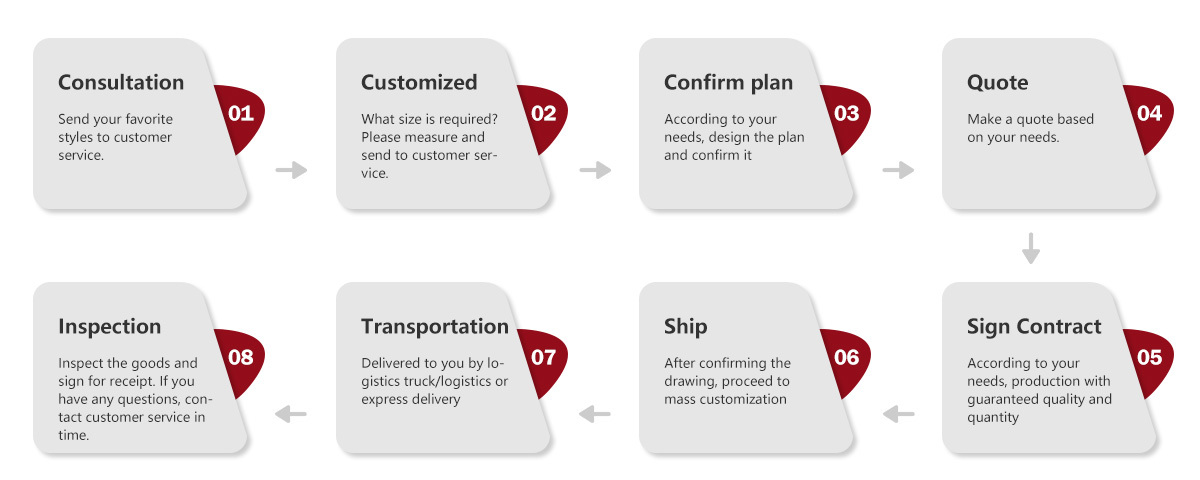

Personalized Customization Process

Product specifications and models, support processing customization

Partner

Qualification

Key words:

Get Quote

Related Products