SRL heat sink

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

SRL heat sink

The finned tube of SRL finned tube radiator adopts the process of winding aluminum fins with steel tube, which is smooth, free of burrs, wrinkle-free and easy to clean. It is easy to remove condensed water on the fin surface during wet cooling in heating and air conditioning engineering, and is not easy to form dust and scale in dry heating and other heat exchange occasions.

- Product Description

-

1. SRL Heatsink Overview

1. The finned tube of SRL finned tube radiator adopts the process of winding aluminum fins with steel tube, which is smooth, free of burrs, wrinkle-free and easy to clean. When wet cooling is carried out in heating and air conditioning engineering, it is easy to remove condensed water on the surface of the fins, and it is not easy to form dust and scale in dry heating and other heat exchange occasions.

2.SRL finned tube radiator is composed of carbon steel frame and steel aluminum fin heat dissipation pipe. The heat dissipation pipe is fixed by frame, with compact structure, good air tightness and convenient installation.

3.SRL finned tube radiator is composed of steel tube aluminum fin tube bundle, which is divided into two rows and three rows along the airflow direction, with a total of 37 models;

4. The working heat medium of SRL finned tube radiator can be steam or hot water, steam (≤ 1.6MPa), hot water (≤ 300 ℃).

5.SRL finned tube radiator has the advantages of good heat transfer performance, high strength, low flow loss, high corrosion resistance, not easy to deform under long-term hot and cold conditions, and long working life.

6.SRL finned tube radiator is mainly used in the air heating system of hot air heating, air conditioning and drying device. It is the main equipment in hot air device. It is widely used in the heating and ventilation system of large buildings in the current industrial and mining enterprises.

7.SRL finned tube radiator model description: ① × ②/③

①, ②-respectively, the radiator length, width size decimeter

③-Number of rows of heat pipe

For example, 12 × 5/3 means that the surface is 1250mm long and 545mm wide, and consists of 3 rows of heat dissipation pipes.

2. SRL finned tube radiator features

1. Compact structure: the use of steel tube aluminum fin tube bundle, close contact, good heat dissipation performance;

2. Cost saving: the price is much lower than the price of the hot blast stove, and its performance-price ratio is high;

3. Careful processing: advanced processing technology, strict quality assurance system, strict organization, careful processing;

4. Easy to install: installation, use, maintenance is simple and convenient, low labor intensity;

5. High cost performance: SRL heat dissipation finned tube is made of seamless steel tube wound aluminum. Due to the high heat transfer coefficient of aluminum, low contact thermal resistance, high strength, thermal shock and mechanical vibration resistance, good thermal expansion performance, and considerable expansion of heat transfer surface.

Technical parameters of 3. SRL type radiator

Table 1. The experimental formula of SRL radiator performance under different working conditions:

Radiator model heat medium Heat transfer coefficient K value kcal/m² h ℃ Resistance mm water column SRLB× A/2 Steam (one gauge) K = 13.1(Vr)0.40 H=0.174(Vr)1.67 130 ℃ superheated water (flow rate 0.023-0.037) K = 14.2(Vr)0.24 H=0.153(Vr)1.58 SRLB× A/3 Steam (one gauge) K = 13.0(Vr)0.43 H=0.309(Vr)1.62 superheated water 130 ℃ (flow rate 0.0154-0.038) K = 12.5(Vr)0.29 H=0.296(Vr)1.58 Table 2. List of SRL finned tube radiator heat dissipation area F(m²), ventilation net cross-sectional area Ff(m²), reference weight W(Kg), installation dimensions, etc.

Model Net cross-sectional area of ventilation (m2) Heat dissipation area (m2) heat medium Number of tube bundles (root) Heating area (m2) Dimensions (mm) Connecting pipe (inch) Weight (kg) A B A1 B1 A2 B2 A3 B3 C SRL 5 × 5/3 0.11 16.7 Steamed

Steam

or

Heat

Water35 0.88 500 400 545 500 575 540 605 570 180 1 1/4" 51 SRL 5 × 5/2 0.11 11 23 0.58 150 38 SRL 10 × 5/3 0.22 34 35 1.76 900 1000 1040 1070 180 83 SRL 10 × 5/2 0.22 22.3 23 1.16 150 50 SRL 12 × 5/3 0.27 42.6 35 2.2 1200 1250 1290 1320 180 99 SRL 12 × 5/2 0.27 28 23 1.45 150 71 SRL 6 × 6/3 0.15 23.6 41 1.24 600 500 635 600 665 640 695 670 180 1 1/2" 66 SRL 6 × 6/2 0.15 15.6 27 0.82 150 43 SRL 10 × 6/3 0.26 39.8 41 2.06 900 1000 1040 1070 180 95 SRL 10 × 6/2 0.26 26.2 27 1.36 150 49 SRL 12 × 6/3 0.32 49.9 41 2.58 1200 1250 1290 1320 180 113 SRL 12 × 6/2 0.32 32.9 27 1.7 150 81 SRL 15 × 6/3 0.39 60 41 3.09 1400 1500 1540 1570 180 131 SRL 15 × 6/2 0.39 39.5 27 2.04 150 94 SRL 24 × 6/3 0.6 95.8 41 4.89 2300 2400 2440 2470 180 197 SRL 24 × 6/2 0.6 63.1 27 3.23 150 138 SRL 7 × 7/3 0.21 31.7 47 1.65 700 600 725 700 755 740 785 770 180 2" 83 SRL 7 × 7/2 0.21 20.9 31 1.09 150 60 SRL 10 × 7/3 0.3 45.7 47 2.36 900 1000 1040 1070 180 107 SRL 10 × 7/2 0.3 31 31 1.56 150 77 SRL 12 × 7/3 0.37 57.2 47 2.96 1200 1250 1290 1320 180 127 SRL 12 × 7/2 0.37 37.8 31 1.95 150 91 SRL 14 × 7/3 0.43 66.1 47 3.41 1400 1450 1490 1520 180 144 SRL 14 × 7/2 0.43 43.6 31 2.25 150 102 SRL 15 × 7/3 0.45 68.8 47 3.54 1400 1500 1540 1570 180 148 SRL 15 × 7/2 0.45 45.4 31 2.34 150 105 SRL 17 × 7/3 0.5 80.4 47 4.13 1700 1750 1790 1820 180 169 SRL 17 × 7/2 0.5 53.1 31 2.73 150 120 SRL 22 × 7/3 0.66 101.3 47 5.21 2100 2200 2240 2270 180 196 SRL 22 × 7/2 0.66 66.8 31 3.43 150 145 SRL15x10/3 0.69 95.2 65 4.91 900 1400 995 1500 1025 1540 1055 1570 180 2 1/2" 215 SRL15x10/2 0.69 63 43 3.25 150 140 SRL17x10/3 0.74 114.4 65 5.72 1700 1750 1790 1820 180 226 SRL17x10/2 0.74 73.6 43 3.89 150 159 SRL 20 × 10/3 0.85 127.5 65 6.54 1900 2000 2040 2070 180 252 SRL 20 × 10/2 0.85 84.2 43 4.33 150 177 SRL 14 × 8/2 0.54 50.7 35 2.55 800 1400 815 1450 845 1490 875 1520 150 2" 108 Production process

Company Profile

The company's main products include fin tubes, fin tube radiators, fin tube heat exchangers, heaters, air preheaters, air coolers, etc. Product materials include steel, stainless steel, steel-aluminum composite, etc., and are widely used in chemical, petroleum, power, electric power, food, textile, printing and dyeing and other industries. The company strives for survival by quality, seeks benefits from management, takes scientific and technological innovation as the driving force for development, regards integrity as the foundation of the enterprise, and establishes a customer-centered business philosophy. Our products cover nearly 30 provinces, cities, and autonomous regions in China, and we have established long-term cooperative relationships with many of the top 500 companies in the country.

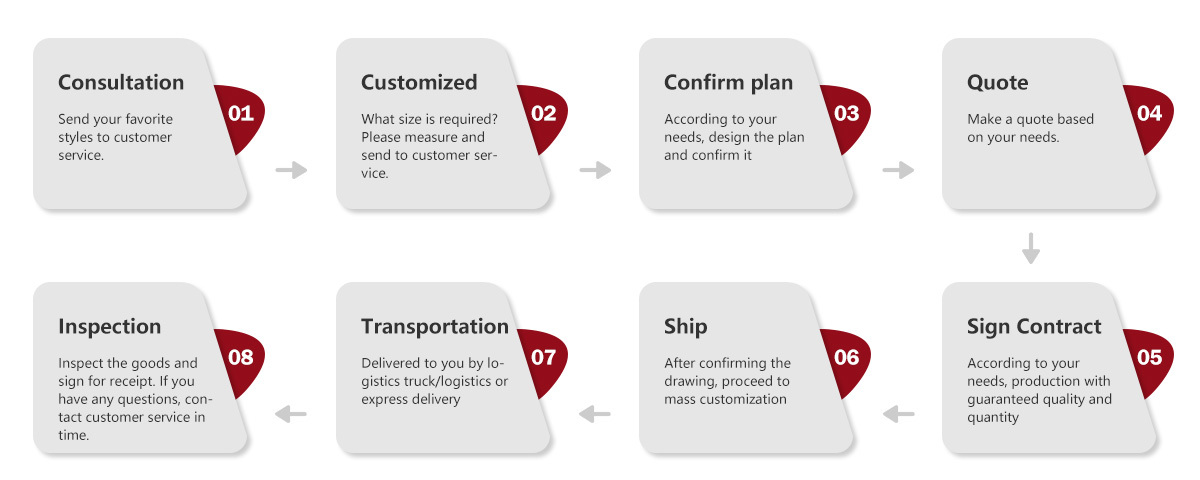

Personalized Customization Process

Product specifications and models, support processing customization

Partner

Qualification

Key words:

Get Quote

Related Products