Finned tube heat exchanger

Focus on the research and development design of finned tube and finned tube equipment

Products

Contact Information

Mobile:+8615503298989

Tel:0086-318-887-7776

E-mail:

hsrongyangnuantong@163.com

Address: No.68 Kaiyuan Road, Jizhou District, Hengshui City

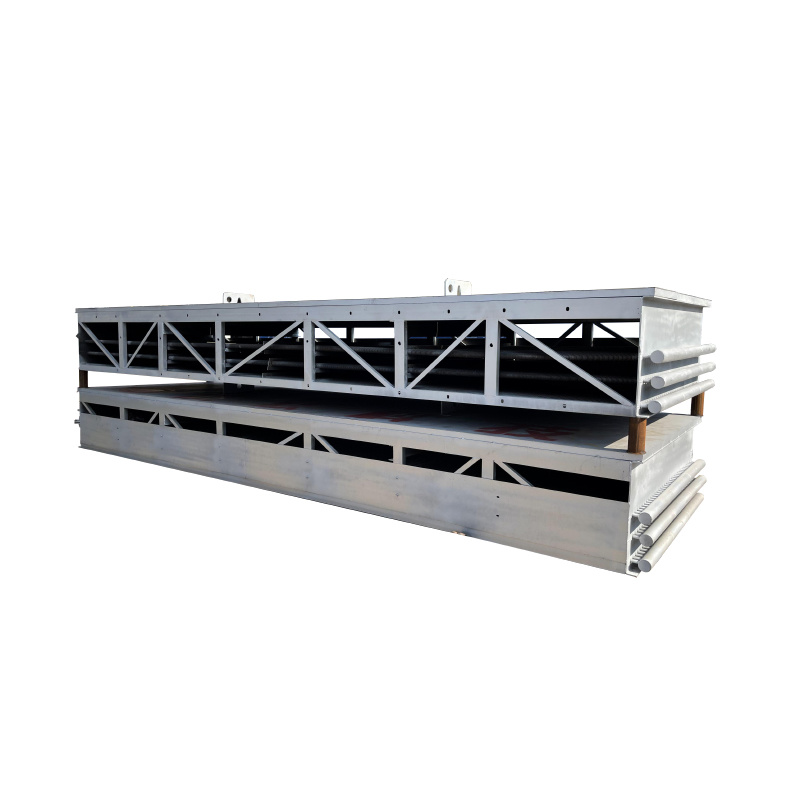

Carbon steel finned tube heat exchanger is a kind of high efficient heat exchange equipment which is widely used in chemical, petroleum, electric power, metallurgy and other fields. Its main feature is the use of carbon steel finned tube as a heat transfer element, with good corrosion resistance and high cost performance.

Carbon steel finned tube heat exchanger is a kind of high efficient heat exchange equipment which is widely used in chemical, petroleum, electric power, metallurgy and other fields. Its main feature is the use of carbon steel finned tube as a heat transfer element, with good corrosion resistance and high cost performance.

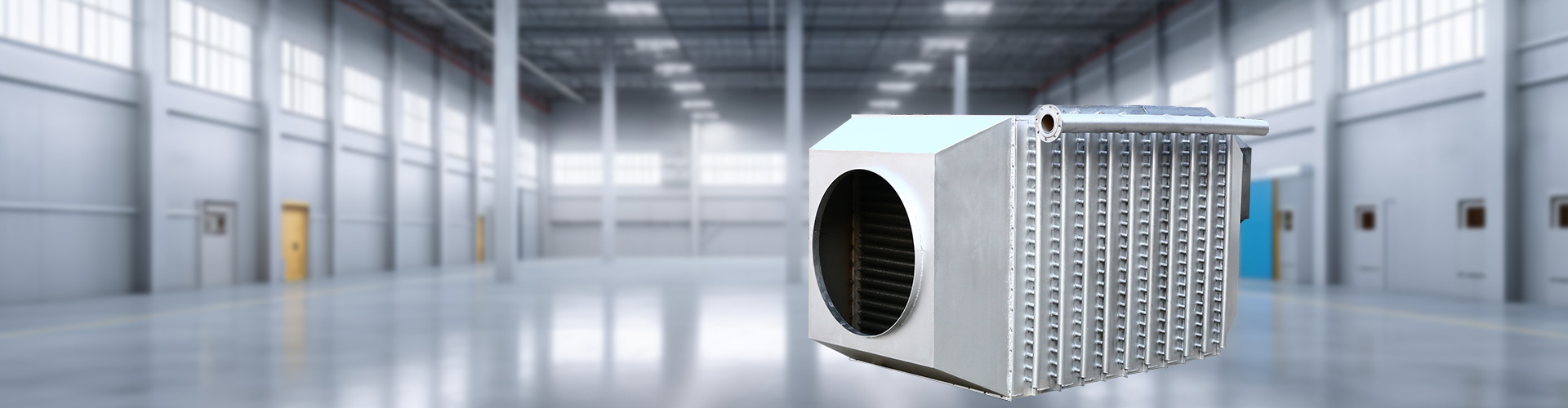

Alloy steel finned tube heat exchanger is an efficient and reliable heat exchange equipment, is a new type of heat exchanger, with compact structure, high thermal efficiency, light weight, high compressive strength. The equipment is formed by adding a finned tube structure, because the finned tube surface has a large number of fins, can increase the contact area between the tube and the airflow, to achieve the purpose of improving heat exchange efficiency.

Alloy steel finned tube heat exchanger is an efficient and reliable heat exchange equipment, is a new type of heat exchanger, with compact structure, high thermal efficiency, light weight, high compressive strength. The equipment is formed by adding a finned tube structure, because the finned tube surface has a large number of fins, can increase the contact area between the tube and the airflow, to achieve the purpose of improving heat exchange efficiency.

The bimetallic finned tube heat exchanger is a combination of two different materials of metal. For example, the steel-aluminum composite finned tube heat exchanger is a combination of steel and aluminum. This kind of radiator has higher corrosion resistance. Performance and compression resistance can effectively extend the service life of the radiator.

The bimetallic finned tube heat exchanger is a combination of two different materials of metal. For example, the steel-aluminum composite finned tube heat exchanger is a combination of steel and aluminum. This kind of radiator has higher corrosion resistance. Performance and compression resistance can effectively extend the service life of the radiator.

The bimetallic finned tube heat exchanger is a combination of two different materials of metal. For example, the steel-aluminum composite finned tube heat exchanger is a combination of steel and aluminum. This kind of radiator has higher corrosion resistance. Performance and compression resistance can effectively extend the service life of the radiator.

A gas-gas heat exchanger (also known as an air heat exchanger or heat exchanger) is a device used to transfer heat from one gaseous fluid to another. It is commonly used in applications of thermal energy recovery, energy conservation and temperature regulation. It is an energy-saving and environmental protection device for heat exchange between the original flue gas and the net flue gas. It is widely used in the fields of desulfurization, denitration and whitening, sulfur alkali washing, flue corrosion protection and so on.

A gas-gas heat exchanger (also known as an air heat exchanger or heat exchanger) is a device used to transfer heat from one gaseous fluid to another. It is commonly used in applications of thermal energy recovery, energy conservation and temperature regulation. It is an energy-saving and environmental protection device for heat exchange between the original flue gas and the net flue gas. It is widely used in the fields of desulfurization, denitration and whitening, sulfur alkali washing, flue corrosion protection and so on.

A gas-gas heat exchanger (also known as an air heat exchanger or heat exchanger) is a device used to transfer heat from one gaseous fluid to another. It is commonly used in applications of thermal energy recovery, energy conservation and temperature regulation. It is an energy-saving and environmental protection device for heat exchange between the original flue gas and the net flue gas. It is widely used in the fields of desulfurization, denitration and whitening, sulfur alkali washing, flue corrosion protection and so on.

Steam-gas heat exchanger is a device that heats water or air with steam as heat source. It can fully replace a large amount of heat value in steam to heat water or air. The heated water or air can be concentrated to all kinds of drying equipment. In modern industry, steam is already a widely used ideal heat carrier.

For the waste heat utilization of waste flue gas, in addition to the form of gas-gas heat exchange for waste heat recovery, in many processes need to use flue gas to heat the process hot water required in the process system or use circulating water to cool the flue gas. At this time, due to the large channel plate heat exchanger, plate thin and other characteristics, can not withstand the liquid pressure, the best heat exchanger selection for the tube fin heat exchanger.